Sometimes getting a project’s capital budget approved is tougher than executing the project itself. That can be even truer for brownfield sites trying to modernize an aging control system. Trying to justify that “something might break and we won’t quickly be able to fix it” is tough to quantify.

Emerson’s Laurie Ben and John Dolenc had a presentation at last fall’s Emerson Exchange conference on the Project Justification Process. It included how to better understand the financial decision investment process and best practices for framing the method.They opened noting the higher failure rate project have as defined by those which overspend the budget by more than 25%, exceed the schedule by 50% or have severe and continuing operational problems into the second year of the project. By this failure definition, 65% of projects over $1 billion USD and 35% of projects under $500 million USD fail.

Based on the Independent Project Analysis (IPA) organization, the process manufacturers and producers that follow best practices on capital project gain 7.5 points of return on investment improving from 15% to 22.5% ROI. Poor performers lose 6% and drop to 9% ROI. Common causes include poor control in early planning, an inadequate match between project and business objectives, and paying too much for capital projects without entirely achieving business requirements.

To improve the ROI on the project, a cross-functional team needs to be involved early in the planning process including the Front End Loading (FEL) and Front End Engineering & Design (FEED) stages. This process of front end loading begins with client internal business planning to assess which projects need to be done.

For an automation project, once a decision has been made that the automation project is a priority, the facility planning begins. A particular plant or a particular process area is identified as one that needs updated automation. Then options are explored for meeting the financial, technical and operational requirements through automation investments.

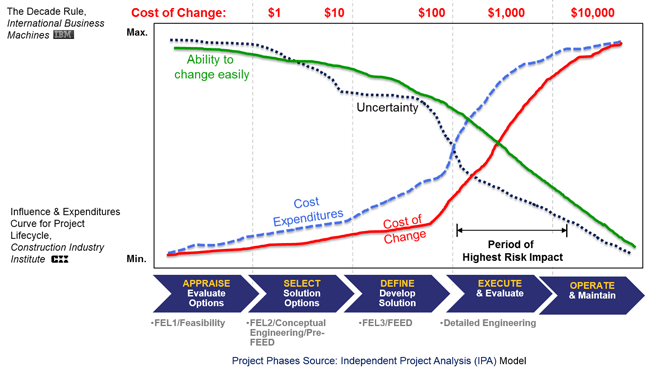

This chart illustrates that early in the project, uncertainty is high, but also the project team has the greatest ability to make changes easily and for very low expenditures. Organizations have the best opportunity to mitigate risk with early planning. This early planning process helps mitigate risks throughout the project.

Laurie and John note that these steps can and should be taken 18 months to 3 years prior to beginning the project and that the larger and more complex the job, the higher importance of developing a plan early. Early engagement and main automation contractor selection prior to the Define phase (FEED) helps with selecting the automation approach and solutions that deliver top quartile projects and operational excellence as well as sets the project up for success and reduces uncertainty, risk and costs.

Changes to scope and contracting are best made at the time when they have the least financial impact to the project. Trying to improve project cost performance in late project phases, execute and operate is rarely successful and drives much of the project failure statistics highlighted above.

From a control system modernization project perspective, Modernization consultants use proven methods to assist in project planning:

- Assess the site’s current situation; help articulate target goals for improvements, and develop a forward action plan

- Situational fluency regarding feasible modernization options

- Recommendations based on conceptual engineering results, benefits estimates

- Estimated schedule of how long the effort should take

- Excellent deliverables for budgeting, justifying, and scoping the project(s)

- Flexibility to define a feasible scope based on time, money and space constraints, as well as target objectives

Over the course of the project, as scope and designs are defined, uncertainty decreases and so does the ability to make changes easily, while the cost of change and cost expenditures increase. The period of highest risk impact is during project execution and the transition to operate.

We’ll address more insights from this presentation in future posts. Until then, you can connect and interact with control system modernization and migration experts in the Improve & Modernize group in the Emerson Exchange 365 community.