Back in March in a post, Safety System Considerations for Process Fired Heaters, I shared some thoughts from a presentation by Emerson’s Nikki Bishop and David Sheppard.

The good news is that their thoughts are now available in a PTQ article, Role of fired heater safety systems. Fired heaters are found in refineries and chemical plants and are:

The good news is that their thoughts are now available in a PTQ article, Role of fired heater safety systems. Fired heaters are found in refineries and chemical plants and are:

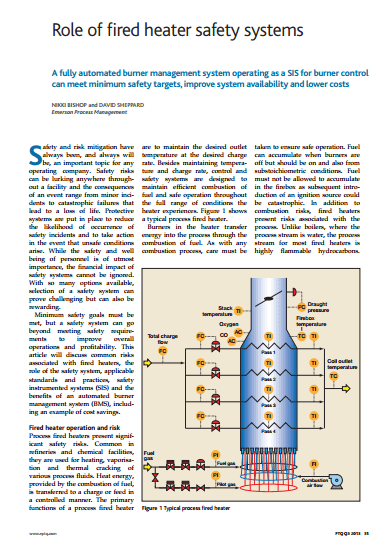

…used for heating, vaporization and thermal cracking of various process fluids.

Control involves maintaining temperature and charge rate through the fired heater, maintain efficient combustion, and operate it safely through its operating range. The control and safety system must prevent fuel from accumulating in the firebox when not in operation. Nikki and Dave highlight a big difference between fired heaters and boilers:

Unlike boilers, where the process stream is water, the process stream for most fired heaters is highly flammable hydrocarbons.

The safety system’s role:

…is to prevent disastrous combustion of accumulated fuel and to prevent overheating and the subsequent catastrophic release of the process stream.

Exceeded limits that can lead to a shutdown sequence include:

…fuel gas pressure and flow, furnace draft pressure, flame detection, process stream flow, combustion air flow, tube skin temperature, stack temperature, per cent oxygen and combustibles…

The authors note that many organizations offer guidance for protective systems including NFPA, ISA, IEC, and API. Some commonly applied standards including NFPA 86 – Standard for Ovens and Furnaces, IEC 61508 Functional safety of electrical/electronic/programmable electronic safety-related systems, and IEC 61511 Functional safety –Safety instrumented systems for the process industry sector. They also point to the ISA/ANSI TR84.00.05 Guidance on the Identification of Safety Instrumented Functions (SIF) in Burner Management Systems (BMS) and the American Petroleum Institute’s API RP 556 Instrumentation and Control Systems for Fired Heaters and Steam Generators.

They note:

…a common trend in all of the standards is the use of SIS [safety instrumented system] for protective actions. …a SIS is a set of components such as sensors, logic solvers and final control elements arranged for the purpose of taking the process to a safe state.

Safety systems can go beyond minimum safety requirements. For burner management systems (BMS), which monitor and control fuel-burning equipment during startup, shutdown, operating, and transient states, and these states can be fully automated to improve operational efficiency. One example is in a reduction in light-off time:

Safety systems can go beyond minimum safety requirements. For burner management systems (BMS), which monitor and control fuel-burning equipment during startup, shutdown, operating, and transient states, and these states can be fully automated to improve operational efficiency. One example is in a reduction in light-off time:

Light-off events for fired heaters may only occur once every two to three years, so the startup procedure may be unfamiliar to operators. Due to the inherent danger associated with light-off, each step in the process must be carefully executed. A manual startup procedure may, therefore, be a lengthy process to complete.

The automated sequence can eliminate human error and show exactly at what step the sequence is currently operating. Diagnostics from smart sensors and final control elements can be integrated with the BMS to provide early warning of fault conditions. Nikki and Dave estimate that reducing the time to startup a fired heater by two hours in a hydrocracker unit can save $100,000-$300,000. The savings will likely be greater on a reformer unit where the margins are greater.

They conclude:

Implementing a fully automated BMS as a SIS for burner control and monitoring can simultaneously meet minimum safety targets, improve system availability and lower costs.