Wireless technology continues to expand across a multitude of applications. One example is in discrete and hybrid manufacturing. In an article, Key Technology Trends for Pneumatic Valve Systems, Emerson’s Adam Gibson describes how wireless connectivity is increasing the intelligence available in pneumatic system components.

One area of wireless connectivity is in the operator displays on mobile devices.

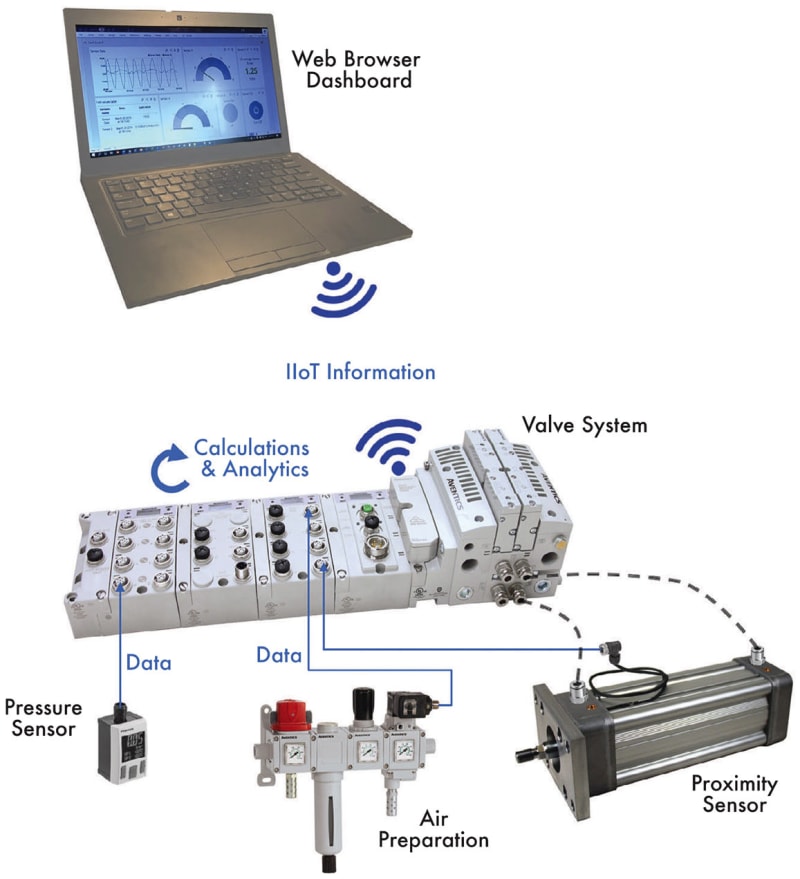

Wireless HMIs [human-machine interfaces] allow operators to respond to issues immediately, rather than having to return to an operator station. These wireless HMIs connect to wireless interface devices that are integrated into standard, high-speed automation network interfaces, such as ProfiNet and EtherNet/IP. These networks are also used to connect machine control and automation functions like PLCs, servos, I/O, and various actuator devices.

The innovative AVENTICS Wireless Auto Recovery Module (Wireless ARM):

The innovative AVENTICS Wireless Auto Recovery Module (Wireless ARM):

…enables easy pneumatic valve system commissioning and configuration, as well as real-time access to pneumatic component diagnostics.

From a monitoring perspective, the pneumatics:

…now ties in with the overall automation system to provide comprehensive, actionable performance data that can improve overall equipment effectiveness (OEE).

By providing actionable performance data to the plant operations team, it enables them:

…to immediately respond to problems and issues with pneumatic components and to correct them before they cause significant problems or lead to significant downtime for automation systems.

Maintenance strategies can be optimized.

Data on valve performance, and whether pneumatic function is falling outside of established thresholds, now provides the basis for more predictive maintenance programs, helping to prevent unscheduled downtime by planning for component servicing and replacement in the most efficient manner possible.

The AVENTICS Series G3 electronic valve system:

…replaces conventional hardwired solutions and integrates communication interfaces and Input/Output (I/O) capabilities to pneumatic valve manifolds.

The Series G3 platform supports a full range of automation communications protocols, enabling:

…PLCs to turn valves on and off more efficiently and to channel I/O data from sensors, lights, relays, individual valves or other I/O devices via various industrial networks.

…

They enable faster start-ups and enhanced diagnostics that help identify problems earlier and faster—contributing to increased equipment uptime and greater productivity.

These Industrial Internet of Things (IIoT) capabilities are enabled by wireless connectivity.

The Wireless ARM module demonstrates a key IoT principle: using advanced digital technology to maximize the uptime and productivity of complex automation systems. Wireless interfaces can simplify and streamline how plant floor personnel or maintenance technicians access diagnostics from pneumatic valve systems. There’s no need to gain access to the machine’s network or download a special app—the real-time, actionable data is safely available via a standard web browser.

Read the article and visit the Pneumatic Valves & Valve Systems section on Emerson.com for more on driving operational improvements with these innovative technologies.