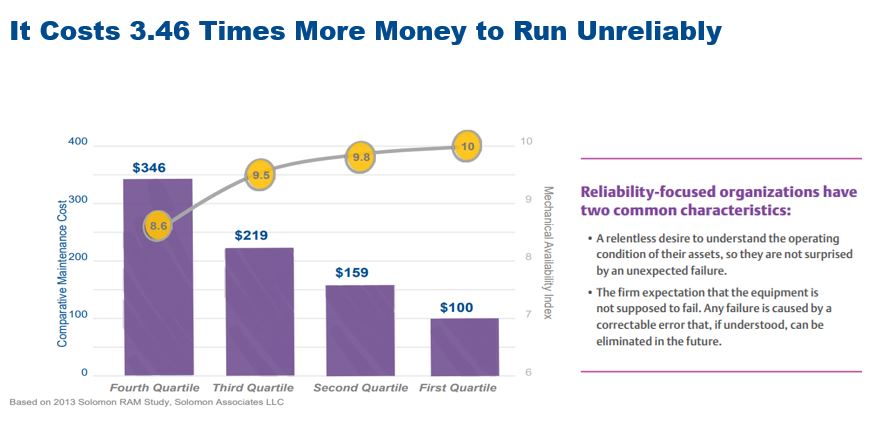

We all know that assets fail. The question is not one of “if” but rather “when” and “how catastrophically”. But what many people don’t know is that the need to repair failing assets is not the only concern with asset health. In his presentation at the 2025 Ovation Users’ Group Conference, Tinh Phan shared that it costs companies an average of 3.46 times more money to run their equipment unreliably. Between unexpected downtime, extra repair costs due to increased wear and tear, expedited part shipping, product waste, potential environmental hazards, and more, even a small gap in asset health visibility can prove quite costly.

“Improving your reliability program and documenting your work processes will help you increase productivity by 7%-10%, and I believe that because I’ve experienced it in the field.”

There is a solution

Fortunately, Tinh shared, implementing predictive maintenance strategies is easier today than it has ever been. First and foremost, reliability technologies have become very easy to obtain and use. Handheld diagnostic tools like Emerson’s AMS Trex Device Communicator are an affordable way to arm field technicians with ways to commission, configure, troubleshoot, and diagnose assets in the field.

Tinh explained that the AMS Trex is rugged enough to withstand the harsh conditions of operating in the field and brings the ability to power devices in the field for testing and configuration. In addition, the AMS Trex provides an app library to allow users to customize their software, helping them perform their specific tasks more efficiently. With a wide variety of apps—loop and Fieldbus diagnostics, ValveLink Mobile, WirelessHART provisioning, Radar Master, and more—technicians can go into the field confident that they have the right tools and expert guidance at their disposal.

“The Trex is very low cost. The return on investment on this tool is a no-brainer.”

Better together

The real strength of a tool like the AMS Trex becomes apparent when it is paired with the facility-wide visibility into data, health, and key analytics offered by AMS Device Manager. The AMS Trex synchronizes automatically with AMS Device Manager, making it easy to store, analyze, and audit data from the handheld devices.

Why does that matter? It matters because AMS Device Manager is the ultimate tool to drive asset health visibility across the plant. It enables communication to assets via manually collected data and wireless sensing devices like the AMS Wireless Vibration Monitor and the AMS Asset Monitor, as well as a wide variety of smart instrumentation. Integrating up to 30,000 devices into a single database, the software gives online access to intelligent instrument and field diagnostics and alerts, delivering a view of device health and troubleshooting information when an issue is found.

“It’s going to tell you what’s going on with that device and how to fix that problem. We’re going to help you significantly reduce your maintenance time and validate whether or not problems are device issues.”

AMS Device Manager provides a “single pane of glass” to combine many standalone systems into a single interface, not only improving maintenance and calibration, but also product support, upgrading, and training and upskilling of personnel. Users can arrange alerts by asset criticality and/or severity to help them quickly decipher which issues need immediate attention.

“Your instruments today are very smart. Most instrumentation you buy today has lots of diagnostic information. You need something to decipher that information.”

AMS Device Manager Data Server—available in AMS Device Manager v15—further improves the capability of the software.

“The Data Server is the latest and greatest. You can export information from level 2 to higher levels, data lakes, analytics, and other resources across your enterprise.”

A more digital future

The companies having the most success achieving operational excellence are laser focused on eliminating extra costs due to outdated maintenance practices. Capturing the losses that stem from unreliable equipment means digitalizing reliability practices. New sensing technologies and device management software are readily available, affordable, and easier than ever to implement and use. Whether the team is tackling renewable energy asset management, remote operations, or traditional generation, there has never been a better time to digitalize reliability systems to eliminate waste and unexpected downtime.