We’ve highlighted the importance of monitoring essential plant assets in several earlier posts. In an upcoming ChemInnovations 2012 presentation, Remote Monitoring of Essential Equipment—An Expert is Always On-Line, Emerson’s Pete Sharpe provides examples of equipment monitoring and remote expert support. This ChemInnovations conference & exhibition will take place November 14 – 15, 2012 in New Orleans.

Here is the presentation abstract:

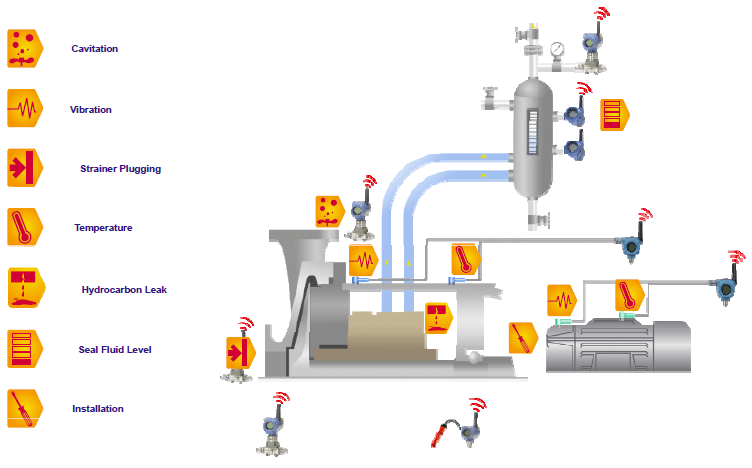

In his first example, he shows how wireless transmitters can be added to monitor for common pump faults including cavitation, vibration, strainer plugging, high temperature, leaks, seal fluid levels, and installation-related issues. For vibration signals coming from the wireless vibration transmitters, statistical performance calculations can find high vibration and increasing vibration levels to provide operations and maintenance personnel with early warning of impending equipment failure.At most facilities, real-time monitoring and protection of critical process equipment, such as large compressors or turbines, is standard practice. However, monitoring of second-tier equipment, such as pumps, blowers, fin-fans and small compressors, has traditionally been deemed cost-prohibitive or too difficult. While these unmonitored assets may not have been originally classified as “critical”, a sudden failure of this equipment can still cause serious process disturbances, shutdowns, slowdowns or further damage to equipment.

Wireless technology has made it possible to justify real-time, on-line monitoring of essential assets as part of an overall site reliability initiative. Low-cost wireless sensors combined with pre-engineered monitoring solutions can automatically diagnose and alert operators and maintenance technicians at the onset of a developing condition. Using a remote connection, experts from around the globe can then access the details and assist with the troubleshooting, root cause analysis and resolution of the problem. A number of leading refiners and operating companies have recently installed wireless essential asset monitoring systems to improve their equipment availability, reduce unscheduled outages and minimize unplanned maintenance activities. This paper will review a number of the installations, the technology applied and the benefits achieved.

For variable speed assets, Pete notes the importance of having a baseline signature chart to be able to compare current conditions against ideal conditions of the rotating equipment through its operating range of speeds. The chart shows the vibration amplitude versus the range of operating speeds. It includes a maximum vibration limit, baseline vibration level, and current vibration.

While alerts can help spot impending conditions, being able to review the detailed diagnostics takes specialized skills. Having skilled experts accessible from remote locations to review the diagnostics is part of a Remote iOps [intelligent operations] approach. For example, if a bearing failure alert is sent to an operator, it can also be sent to the Remote iOps location to review the vibration signatures and compare against baseline. If required, the replacement bearing and work order are scheduled to fix the problem before a failure condition occurs.

In an earlier post, Essential Asset Monitoring at UT Separations Research Program, we highlighted how these Remote iOps were developed and tested in collaboration between the Emerson Asset Optimization team and the University of Texas Separations Research Program pilot plant. Pete highlights how remote experts are monitoring pumps, boilers, and blowers in this facility.

The combination of wireless sensor technologies and global internet communications open up the capability to monitor more essential plant equipment and connect the diagnostics with experts to provide multi-site, 24×7 essential equipment monitoring. If you’ll be at ChemInnovations this year, make sure to connect with Pete and the rest of the Emerson team.