Over on the Emerson Process Experts Facebook page, I was asked if I could do something on the subject of alarms in control systems. Alarms are the visual and/or audio indications for plant operators identifying an abnormal condition (equipment problem, process deviation/upset condition, etc.) that requires a response.

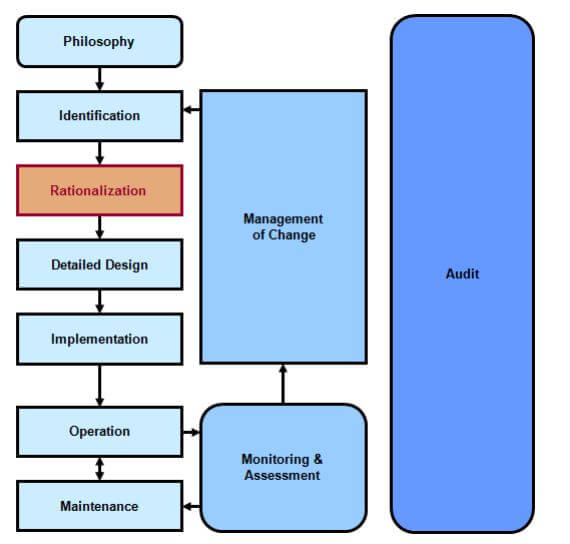

I saw a news item in my DeltaV News RSS feed about a new Alarm Rationalization whitepaper. This rationalization phase is described in the ANSI/ISA-18.2-2009 Management of Alarm Systems for the Process Industries standard. This standard:

…addresses the development, design, installation, and management of alarm systems in the process industries. Alarm system management includes multiple work processes throughout the alarm system lifecycle. This standard defines the terminology and models to develop an alarm system, and it defines the work processes recommended to effectively maintain the alarm system throughout the lifecycle.

This rationalization phase helps to sort out, based on the plant’s operating philosophy, what qualifies as an alarm. The whitepaper’s author, Emerson’s Kim Van Camp summarizes this rationalization process as:

…a systematic work process to evaluate all potential or existing alarms against principles established in an alarm philosophy document, to qualify which are legitimate alarms, to specify their design, and to capture rationale such as cause, consequence and corrective action which can be used to guide operator response.The principal benefits of alarm rationalization are reduced alarm load on the operator, elimination of nuisance alarms, and prioritization to help the operator respond to the most critical alarms first, all of which lead to improved operator effectiveness.

While in many facets of our lives where more is better, when it comes to alarms, this is definitely not the case. The rationalization process helps reduce the overall number of alarm activations and nuisance alarms (chattering, fleeting or stale alarms). This also means that when alarms do occur, they are more trusted, are accompanied by well thought out operator guidance, are prioritized for correct action sequence, and are free from clutter of secondary and often redundant alarms.

Effectively rationalizing the alarms is a team effort. The whitepaper identifies many stakeholders including:

- Production and/or Process Engineers familiar with the process workings, economics, and with the control system

- Operators – preferably two operators from different shift teams with experience in use of the control system

- Process Control Engineering – particularly when advanced control strategies or ESD logic are discussed

- Safety and Environmental Engineers (part time as needed)

- Maintenance / Equipment Reliability (part time as needed, usually when specific equipment is discussed)

- Management (Kick-off)

- Instrumentation/Analyzer Specialists (part time as needed)

- Alarm Management Facilitator

Inputs to the process are a well-designed alarm philosophy to establish the rules and key performance benchmarks. For existing plants, current alarm performance should be benchmarked to understand current alarm loads, common nuisance alarms, and frequently occurring alarms.

The whitepaper describes tools and expertise to aid in this rationalization process including SILAlarm by exida, operator alarm response procedures using DeltaV Alarm Help, analysis and benchmarking of alarm system performance with DeltaV Analyze and Plantwide Event Historian, and the alarm management specialists of exida and Emerson.

Kim walks the reader through an example of the rationalization process using these tools. It gives a flavor of the process and what to expect once the rationalization process is complete. If you need to improve the performance of your alarms to improve overall operator effectiveness, take a look at the whitepaper and the ten tips for effective rationalization it offers at the end.

Update: Welcome readers from Gary Mintchell’s Feed Forward blog. I welcome any thoughts you have on the subject of plant alarms.