Manufacturers & producers are addressing industry challenges using technology and digitization. With initiatives such as Digital Transformation & Industry 4.0, they are changing manual practices and moving towards automatic, digital, and data-driven ways of working.

I caught up with Emerson’s Manasi Menon on the role analytics plays in digital transformation initiatives. These businesses want to use analytics to make sense of this digitized data from smart instrumentation and Industrial Internet of Things (IIoT) devices and use actionable insights from it for decision making and improved operational performance. Whether it is energy monitoring, asset reliability or process optimization, they want to use real-time analytics and predictive insights to improve business performance.

Analytics in an organization typically falls into two major categories—business analytics used for organizational support functions such as HR, IT, Supply Chain, Finance, etc. and operational analytics used for improving the production of the plant and the process itself.

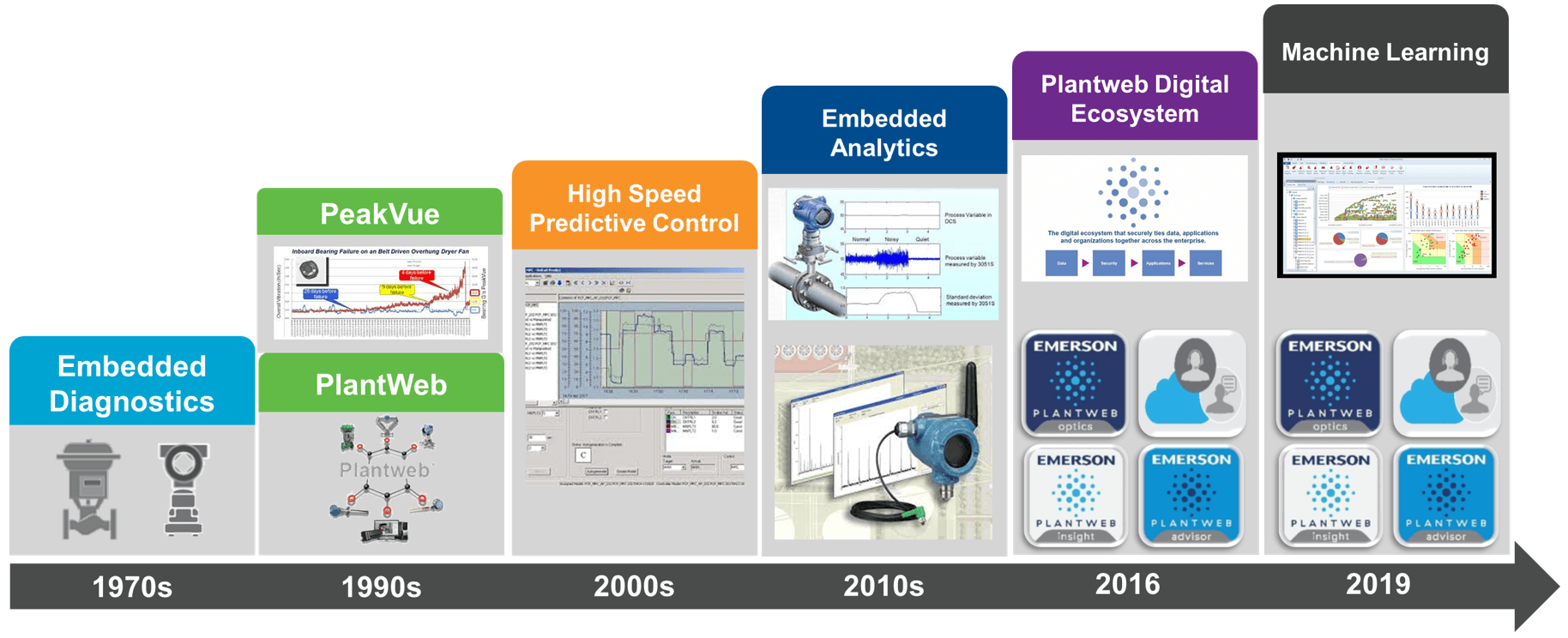

Emerson has more than 30 years of experience in operational analytics-based applications, which began with embedded diagnostics in smart instrumentation and control systems. AMS Device Manager was developed to collect, analyze and present these diagnostics to users. Ever more sophisticated analytics added over time include PeakVue machinery analysis technology, embedded in the DeltaV and Ovation distributed control systems and the addition of KNet Analytics advanced process data analytics & machine learning software.

Emerson has more than 30 years of experience in operational analytics-based applications, which began with embedded diagnostics in smart instrumentation and control systems. AMS Device Manager was developed to collect, analyze and present these diagnostics to users. Ever more sophisticated analytics added over time include PeakVue machinery analysis technology, embedded in the DeltaV and Ovation distributed control systems and the addition of KNet Analytics advanced process data analytics & machine learning software.

Manasi explained that these operational analytics can be classified again in two categories—principles-driven analytics and data-driven analytics. Principles-driven analytics are based on theory, physics, and known thermodynamic laws that have existed for decades. Data-driven analytics are based on statistical modelling, pattern recognition & machine learning. Statistical models have also existed for decades but what has changed is the processing power and the computational ability to run these statistical models iteratively on real-time data to be able to predict key issues with process/plants or assets.

A distillation column is an example where both types of analytics can be used. Principles-driven analytics can be applied to known issues around some of the components in the unit including boilers and pumps. Data-driven analytics assist in understand the correlation of the various assets and process parameters and their impact on the process/column itself. So for the distillation column, data-driven analytics help to predict separation issues or column flooding based on information gathered from upstream or downstream of the column.

Here are some other examples of using both types of analytics for reliability performance improvements. For each of these, KNet Analytics is providing both the principles driven analytics and data driven modelling as one combined solution/ model.

- Heat Exchanger. Using principles-driven analytics to calculate the fouling factor and using data-driven/modelling techniques to predict fouling over time

- Pumps. Using subject matter expertise to predict known faults such as bearing mis-alignment or vibration issues and using data-driven techniques to predict remaining useful life

- Compressor. Using principles and domain expertise to calculate compressor efficiency and using data-driven techniques to predict surge conditions remaining useful life

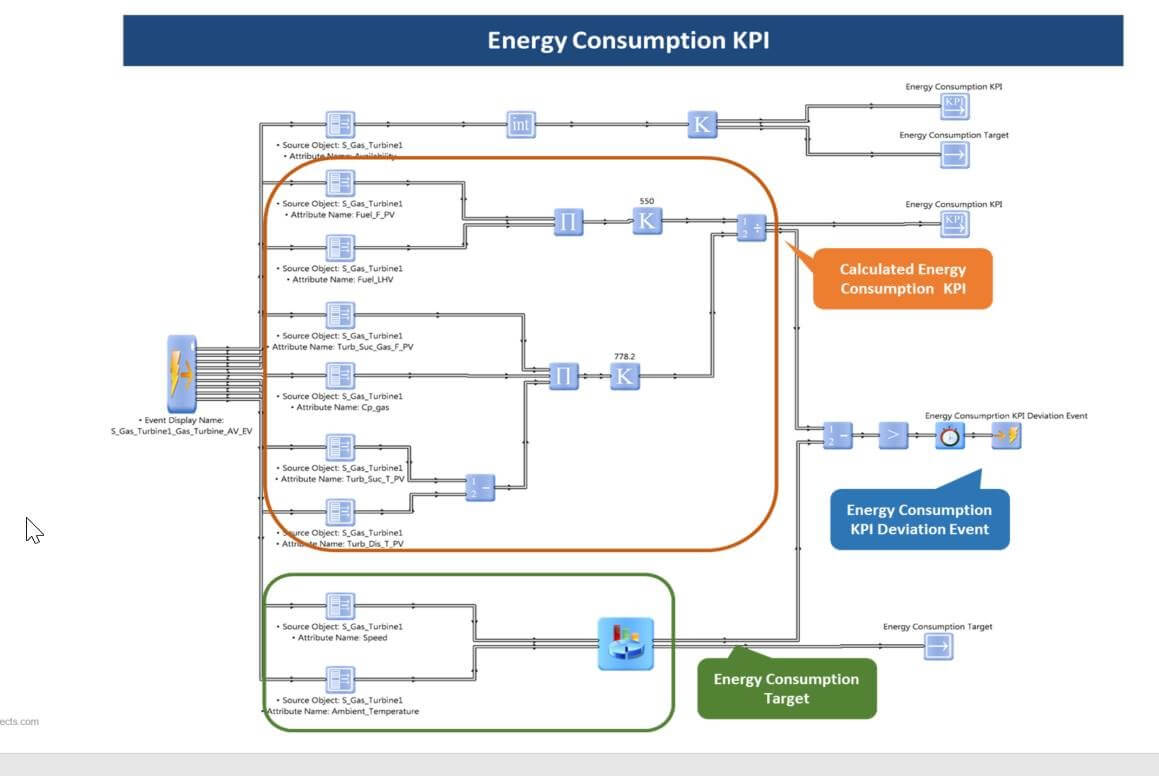

From an energy efficiency performance improvement perspective, using physics and thermodynamic laws enables energy consumption calculations of an asset such as a boiler. Comparing that boiler’s energy performance with dynamically changing energy targets is where data-driven techniques, such as multivariate regression models, can be used to create energy consumption baseline targets in-real time.

Here’s a KNet Analytics example of a data-driven model of an energy consumption target. It includes a calculated energy consumption KPI which is principles-driven analytics-based. Together, they result in a holistic model looking at both and providing more effective KPI deviation event detection.

Visit the IIoT Analytics: Plantweb digital ecosystem section on Emerson.com for more on using these analytics to derive actionable information to improve business performance. You can also connect and interact with other operational analytics experts in the IIoT & Digital Transformation group in the Emerson Exchange 365 community.