At home, a few measuring cups and spoons are all we need to follow a recipe. A pinch more or less rarely makes a difference. But in industrial food production, precision isn’t optional; it’s essential. Consistent processes and uniform products demand accurate measurement, and that means weighing ingredients rather than relying on volume.

Liquids present an added challenge. Their density can vary, making volume-based measurements unreliable. That’s why mass flow measurement is the gold standard for liquid ingredients. Coriolis technology, like our Micro Motion product family delivers the accuracy and reliability food manufacturers need, as we discuss in our article in Food Engineering, How Coriolis Meter Advancements Can Support Food Manufacturing.

Coriolis meters measure true mass with accuracy, even as process conditions change. These meters also provide simultaneous measurements of both density and temperature. These measurements can often be combined to create a variety of inferred measurements useful to food processing, such as air entrainment, level of solvent in oil and the strengths of acids or bases.

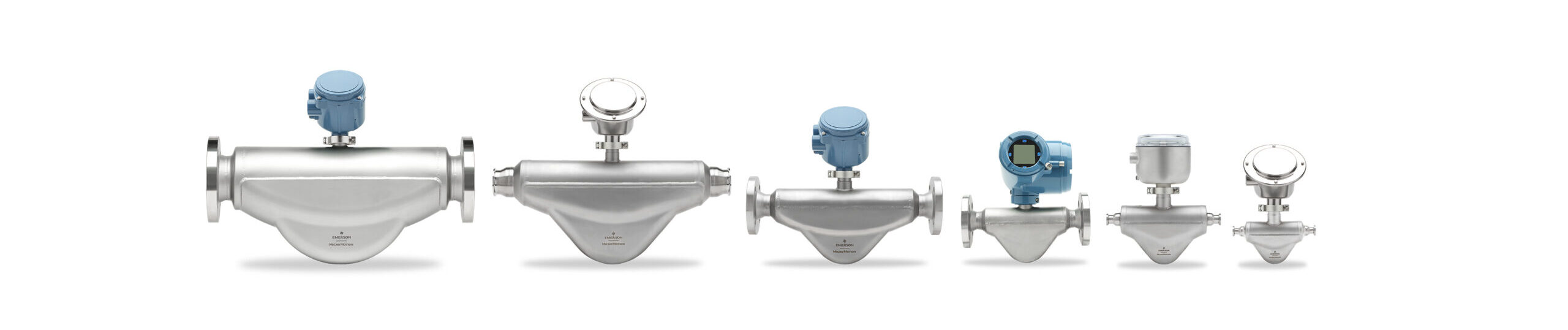

Historically, one of the main drawbacks of Coriolis technology was a long face-to-face dimension. The new ultracompact G-Series Coriolis Flow and Density Meter has a face-to-face dimension much smaller, nearly half in some cases, than some legacy designs. These meters now come in a hygienic, cleanable and drainable option as well.

New Coriolis sensors are lighter and take up less space than legacy sensor designs, while maintaining the same level of accuracy. A typical legacy-design, dual tube 1-inch Coriolis sensor may have a face-to-face length of 20 inches, with the body extending down more than 9 inches from the pipe centerline. The 1-inch model sensor now is less than 12 inches long, with the body extending less than 4 inches off pipe centerline, reducing the overall installation space by a factor of nearly four.

Beyond hardware improvements, new transmitters extend the power of these units by analyzing processes and providing critical production data through a range of built-in and optional features. Many legacy Coriolis sensors can even be upgraded by simply transitioning to a newer transmitter.

A partial list of the software advancements includes:

- Smart Meter Verification can fully check the functionality of the meter, either on a schedule or on demand.

- Concentration measurement software can calculate °Brix, °Plato, °Balling, °Baume, %HFCS, %HNO3, %NaOH, and other concentration measurements.

- Advanced Phase Measurement can measure entrained air, gas void fraction, and provide gas/oil/water mixture measurements.

- Fuel efficiency software provides the information needed by energy measurement software applications.

- Data historian with a real-time embedded clock can store data for extended periods of time.

These capabilities make it far easier for producers to maintain product quality and consistency, even with the most complex and sensitive recipes, assuring efficient and profitable performance.

When faced with a new or existing flow measurement challenge, users should consult with their Coriolis flowmeter salesperson to fully understand the assortment of sensor and transmitter options that are now available. The latest technological advances make Coriolis even more capable, and more affordable, than ever before.

To learn more, visit the Flow Measurement Systems pages at Emerson.com. You can also connect and interact with other engineers in the Food & Beverage and Life Sciences Groups at the Emerson Exchange 365 community.