Maintaining the integrity of these pipelines is paramount for safety and the environment. I received a great presentation from Emerson’s Marc Buttler on the subject of pipeline leak detection that I wanted to recap in this post.

There are many standards and guidelines governing leak detection. Here are some of the most prominent ones:

-

API (American Petroleum Institute)

- 1130 (2007 / Updated 2012) – Computational Pipeline Monitoring (CPM) for Liquids

- 1149 (2008 / updated 2015) – Pipeline variable uncertainties and their effects on leak detection

- 1155 (1995 replaced by 1130) – Evaluation and methodology of software-based leak detection systems

- 1175 – Leak detection program management

- TRFL – Technische Regel für Fernleitungen (Technical Rule For Pipelines) (2003)

- TUV accreditation (Germany)

-

CSA Group

- Pipeline Safety

- Z662 –Annex E (2015) –Same as API 1130

-

- DTPH56-11-D-000001 -Leak detection study

- 49 CFR part 195

-

NSTB (National Transportation Safety Board

- SS0502-Role of SCADA in leak detection

When considering pipeline monitoring technologies, criteria should include monitoring sensitivity, reliability, robustness, accuracy, response time and system cost. To achieve the sensitivity, reliability, accuracy and robustness criterion, hybrid leak detection systems have either multiple systems with separate alarming or integrated systems with common alarming.

The statistical method of leak detection analyzes pressure and flow deviations. This approach is relatively simple to install but hard and expensive to tune and lacks sensitivity, reliability and accuracy.

The pressure wave leak detection method measures a wave in the fluid caused by a leak. This method provides high accuracy and detection time and is good for larger leaks. Accuracy is lacking for small leaks and theft and this method is not as robust or reliable.

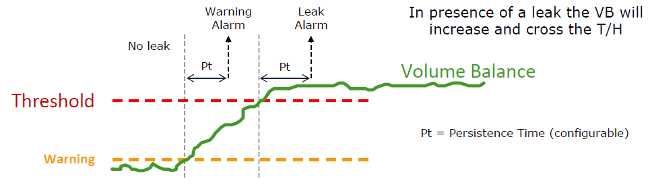

The real-time transient model (RTTM) leak detection method performs a volume balance calculation based upon the inflow and outflow less the volume packing rate. This method has good sensitivity, accuracy, robustness and reliability but takes more to install than other methods.

PipelineManager solution for real-time pipeline monitoring

Some other methods include mass balance and model-compensated mass balance and rarefaction wave.

RTTM is the best solution for internal natural gas leak detection. It is the only technology that addresses all the API 1130 criteria. It uses time averaging periods to detect various sizes of leaks—short periods for large leaks and long periods for small leaks. Dynamic alarm thresholds are set to minimize the chance of false alarms. Location of the leaks is calculated by the proportion of upstream and downstream imbalance.

A typical architecture includes real-time and historical databases from the SCADA or DCS system controlling the pipeline, operator and engineering stations, Emerson’s PipelineManager software performing real-time leak detection with a primary and secondary real-time model server, VisualPipeline operator stations and accessories for backup and printing.

Visit the Pipeline Integrity & Leak Detection section on Emerson.com for more on ways to maintain pipeline integrity. You can also connect and interact with other pipeline operation and management experts in the Oil & Gas group in the Emerson Exchange 365 community.