This is a big week for some of the major process manufacturing sectors. The Offshore Technology Conference (OTC2012) is going on through tomorrow in Houston, Texas and Interphex 2012 for the Life Sciences industry through tomorrow in New York City. These are definitely two industries with unique business challenges, processes, and operational challenges. In Twitter, you can follow the OTC action at #OTCHouston and the Interphex action at #Interphex.

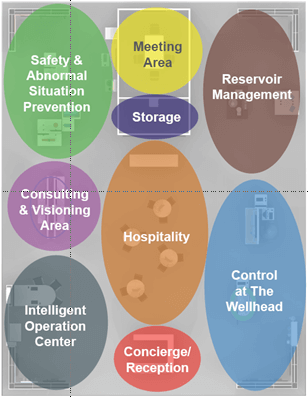

At OTC, the Emerson oil and gas experts are in booth 4771. They are sharing ways technology and expertise can help oil and gas producers to maximize production and extend the life of existing fields. The areas impacted include reservoir management, control at the wellhead, integrated operations (iOps), and safety and abnormal situation prevention.

At OTC, the Emerson oil and gas experts are in booth 4771. They are sharing ways technology and expertise can help oil and gas producers to maximize production and extend the life of existing fields. The areas impacted include reservoir management, control at the wellhead, integrated operations (iOps), and safety and abnormal situation prevention.

Improvements in these areas lead to shorter time to first oil, reduced maintenance and regulatory compliance costs, and optimized oil and production and processing through the point of custody transfer. An example of how this is done is in integrated operations, which is about collaboration between disciplines such as reservoir geology, well planning, logistics, production, drilling and well maintenance, and equipment maintenance. These disciplines can extend beyond business units, suppliers, and geographies.

The source for better decisions is the data coming from asset diagnostics, process variables from the production process, operational performance metrics, and safety system status. We’ve touched on many of the ways this information is provided in posts such as The Peaks Provide the Early Warning in Machinery Protection, Custody Transfer Flow Measurement, and Seismic Inversion, Attributes, and Oil Field Planning.

For instance, around the business objective to shrink the time to first oil, advanced diagnostics during the startup process using tools such as AMS Device Manager and AMS Machinery Manager help eliminate installation errors and speed up troubleshooting. Technology can also be deployed to connect in remote experts collaboratively—from either within the oil and gas producer’s organization or externally with trusted partners. And technologies such as IEC 62591 wireless devices and electronic marshalling reduce the impact of late project changes and difficult wiring pathways.

If you’re in Houston and in the oil and gas business, stop by booth 4771 and talk with the team about some of the other areas such as reservoir management, safety, control at the wellhead, and integrated operations. Based on your business objectives and priorities, one or more of these areas can likely help you maximize production and extend the lives of your oil and gas fields.

Update: I updated the phrase “intelligent operations” to “integrated operations” per the standard industry terminology.