Emerson’s Anand Iyer continues his series on Cloud I/O with a look at snapshot processing and controller swaps.

Once upon a time, more than a decade ago, we faced a problem on a column, which seemed to open up our minds to a wonderful world of possibilities loosely termed as Profile Based Controls. Now, I have been in the desert riding in a car towards an onshore facility or riding a boat to an offshore platform or to a plant that probably has no columns and all of a sudden, a thought would come on how the column’s profile could be controlled.

The concept of Profile Based Controller was based on certain types of actions (over the basic PID action).

- Have many control modules that would give output in some algorithm (ratios to different outputs in a conventional way) and or controller swaps. For example, a column could have several temperature control modules each trying to manipulate the steam input at an optimum level and the steam output would prioritize based on the most critical parameters (ensure that bottom temp is maintained at correct level, followed by one level up and so on).

- Snapshot controller: This is like a recorded history of actions taken on a disturbance and plays the outputs whenever the disturbance is triggered.

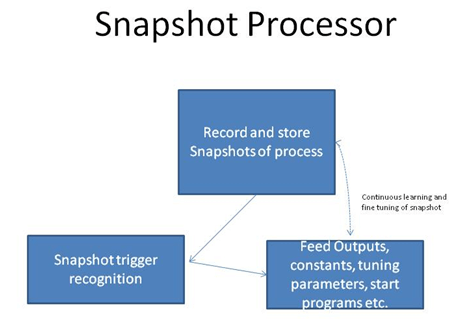

Snapshot Controller. The snapshot controller is a controller that stores snapshots of process parameters like process variables, setpoints, outputs, sometimes tuning parameters and constants for different states of the process such as steady state, disturbance states—pump changeover or one pump trips and another picks up and reactor startup/shutdown and certain infrequent disturbance occurs.

Suppose in a reactor, you try PID control of the temperature, but based on the actual reaction happening in the reactor, the PID loop tuning could be a big problem. You have an operator who controls it manually, based on his previous knowledge of the process or intuition. One way would be to feed back this operator action to the reactor for repeatable performance—PID could be a backup.

In DeltaV Simulate, we do take process snapshots and feed them back. However, as of now this feedback is more a kind of all parameters being written back. What is required is a controlled selection of parameters and a processor, which will store this snapshot and feed back to the process—say at the press of a button.

After a snapshot is stored, there is a need for a snapshot recognition mechanism. How does the system know when a particular snapshot is triggered? This could be a simple event, such as pump changeover detection or more complex systems.

Also, there could be a need for an interface for the operator to select different snapshots and feed them (i.e. he may write a set of output, constants, tuning parameters at one go).

And looking above there could be a need for automatic input or with operator confirmation input to feed different snapshot outputs to the system.

We can summarize the following:

- Snapshot processors store snapshot information about different process conditions in different snapshots.

- Snapshot processors have algorithms to recognize these snapshots.

- Snapshot processors feed values 9outputs, constants, tuning parameters and other functions to IO bubbles.

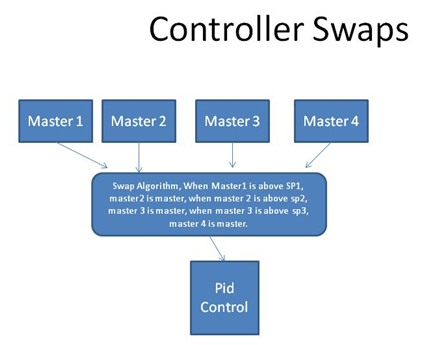

Controller Swap Basic. A controller swap is basically a control selector, except that the process prioritizes the process variable (PV) band of each control module and selects one PV after another—streamlining the profile on a continuous basis. In short, this has more to do with maintaining the quality of the process.

For example, take a column say, the bottom temperature. It has maximum priority for steam flow control. The steam flow controller chooses it as a master. As soon as this temperature is within a specified band, it goes to the next temperature and so on till the column profile is optimum.

If at any point, the bottom temperature were to be disturbed to a lower-side trigger, then the control would switch to the bottom temperature as master again. For example, if the bottom temperature should be 171 degC minimum, then perhaps at less than 171.1, the master temperature control switches back to the bottom temperature.

We could add some more complexity where the feed of the column is also fine-tuned to increase (throughput) to maintain Master 3 and Master 4. Master 3 and Master 4 would also be in another swap algorithm to increase the middle feed.Other advanced algorithms could either act on these swap algorithms or play around with the swap setpoints (SPs) mentioned above (SP1 to SP4).

The concept of I/O clouds will make many such complex algorithms an easy possibility in the future.