Emerson’s Anand Krishnan Iyer brings his unique perspectives to cloud technology—specifically around clouds of control system I/O. Today’s post kicks off a multipart series exploring the possible future of these I/O clouds.

Clouds. Monsoon clouds mean a lot to us. Right from the Indian farmer to the stock market analyst, monsoon clouds rule their lives. This year, the clouds were missing in June and part of July. Doomsday was predicted and stock markets were planning to plunge. My one thought was that I could live one monsoon without buying a few umbrellas (I lose a couple every monsoon). And by now, the rains have been sufficient that this is no longer a worry and luckily, I have been at different sites, so I did not have to buy umbrellas.

Clouds may mean many things:

- In the hot Middle East desert, the cloud is ever welcome in the summer.

- In Germany (as in many colder countries), the clear sky (or lack of clouds) is widely welcomed.

- Clouds could mean less solar energy to your solar panels.

- Clouds could mean rain to a farmer.

It all depends on your perspective.

Clouds are made of tiny particles, could be dust, smoke water and so on…

The IO cloud is a cloud of IO’s of the control system world. These IO’s are not merely the information read by the sensor and translated to some meaningful reading, but a bubble of information that could mean different things to different processors in the control system environment. But first, it is necessary to answer an important question.

Why IO cloud? Is it just a “fanciful” thinking or the logical future of IO’s? Frankly, in true technocratic spirit, we would like to think of grandiose plans like piezoelectric floors at all airports, railway stations and malls so that so many people walking for their daily commute or amusement would generate electricity. Though this could someday become reality, till such time, it is just science fiction.

As technocrats and specifically control system technocrats, we often rile at the fact that control systems have progressed little in the last decades. In fact in the last century, we have hardly come ahead of the PID algorithm, except move it from platform to platform (hydraulic, pneumatic, electric, microprocessor based, and moving systems from one windows version to another). But looks like the next few years could see lesser platform-to-platform movement and more addition to the control system knowledge and daily usage in different industries.

The most important question in the present discussion is, if the IO cloud is actually a beneficial future or a mere concept that can be classified as science fiction. This series of articles tries to highlight in very simple terms, how the IO cloud could be a most beneficial future for all the end users. The IO cloud system could take control systems to an intuitive processing environment that could give large economic and quality benefits to the users.

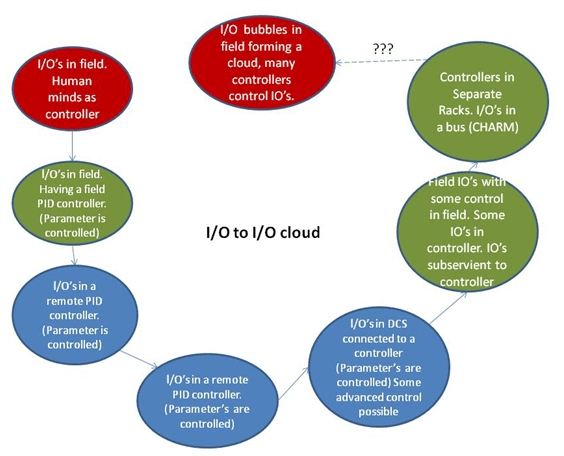

IO-to-IO cloud: a journey of control system IOs… Looking at the journey of IO systems, and extrapolating to the future, IO clouds seem to be the next logical step.

Dawn of the journey. Let’s start from the earliest control system readings. The simple marked sight glasses, Bourdon gauges which provided visual indication of the process parameters and thereby the process were probably a very first measurement. You could possibly have a valve that you operated manually or a gas pressure to a burner that you could operate to regulate the temperature and so on. This is the earliest IO concept where a lot of the IO processing is done by the human mind.

If we break down the process:

- A physical measurement is represented in a simplest of manner.

- There is some signal conditioning done by the human brain including perhaps some diagnosis of the measurement (the glass is dusty, the gauge’s zero is out by 2 %) and so on.

- Then came the computing done by the brain as to how many turns you need to close, open the valves to regulate the temperature or process to desired parameters.

- Finally, there is the act of opening or closing the valve.

Middle ages. So finally we came to the concept of a transmitter where a measurement is done, some signal conditioning happens and is represented in a remote place (generally the control room) through hydraulic, pneumatic, and electric means.

Computing of how much the output needs to be adjusted is done by the PID controller with a setpoint and the output is as adeptly transferred to a final control element.

Pneumatic PLC’s, relays, provide some of the safety functions.

Early modern age. The first DCS and PLC systems integrate a number of such inputs and do some advanced processing. IO cards collect IO information and then base processing is done by the control systems and advanced processing is possible by having more top-level layers to the base controls.

Early field bus systems try to provide the IO processing in field along with some basic control being done in the field. The controllers still reside inside the control room.

IO’s are still inside the domain of the controller. They are assigned and downloaded to specific controllers.

Coming to today. Electronic Marshalling technology puts the IO information at par with the controller information and is probably the first predecessor to the IO cloud system. The IO’s are still bound to a controller and provide a transition path from legacy to future IO systems.

It is worthwhile to note that the Safety systems are already governed by the IEC, ISA and other standards governing the Safety Instrumented systems. Hence, this discussion does not propose any dramatic change to the Safety Instrumented Systems.

Also the ISA guidelines on Control system cyber security provides guidelines on securing the control systems from external threat and these articles do not provide any replacement or alternatives to these guidelines.

The ideal IO cloud of the future. The Ideal IO cloud of the future would consist of independent IO’s providing information about the specific IO or group of IO, to all the processors in the control system domain. The IO cloud would also draw instructions from the Processors in the control system domain.The important change from the Electronic Marshalling approach would be that the IO would not be bound to a specific controller. It could also be CHARMs-Fieldbus–Wireless-THUM adapter combo-technology providing real-time information about the IO to a pool of processors.

Further these series of articles also proposes more roles to the IO information , more alternative processing options for better economic (lower cost per product quantity), better throughput (higher product quantity at lowest possible cost), required quality (best required quality).

Further, though it does not replace the Safety Instrumented systems, it will also provide additional secondary and tertiary level safety.