Tank storage facilities are critical in the supply chain from feedstock production through mid-stream and end user distribution. At last summer’s Emerson Exchange Düsseldorf conference, Vopak‘s Louis Janssen and Emerson’s Cor Vermeijs presented, Improved terminal operations by terminal automation. Vopak provides independent storage and transshipment downstream of production, refining, and products transmission, and upstream of final distribution.

In the presentation, they described the process for improved terminal operations by looking at the workflow from order intake to service delivery—integrated vertically and horizontally. The current landscape of the architectural layers from the field instrumentation through the process control, operations management, and enterprise resource planning (ERP) levels was, at some levels, a mix of many systems.

Some of the requirements for improvement included taking a process focus for the operators, developing a best practices exchange platform, developing standardized specifications, identifying and segmenting company and supplier core competencies, selecting leading technologies, standardizing connectivity with ERP systems, and reducing overall time to market. Movement control was key to realizing the operations focus around customer priorities and overall efficiency.

Mode of operations across the various terminal sites included manual, remote manual, automated, and integrated from the physical process through the business transactional processes. As measured by manipulations per operator, the efficiency of the operations increased with the level of automation and interconnectivity with the business systems.

Beyond quantitative efficiency metrics, it was important to improve qualitative factors including overall process safety, personal safety, service levels, process integrity and robustness, and the capture of process knowledge.

Over the course of several years, a strategic plan was formed and executed including the control and information architecture, automation blueprint and governance model, terminal automation system piloting, technology provider short listing, large-scale roll out, and plan alignment and recalibration.

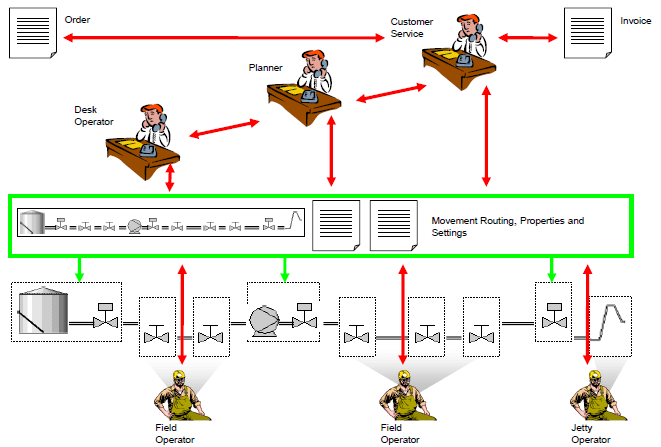

They shared a before-and-after example of the path for product and business processes from tank to jetty—where the tank storage products were loaded for further supply chain transportation. The process involved multiple interactions between customer service, planners, desk operators, field operators, and jetty operators—each with a span of control around different parts of the process.Through automation and integration across the levels from field instrumentation through the ERP system, each organizational function had access to a common movement routing system to streamline the process from order to invoice.

Creating this common platform for all business functions to interact not only captured knowledge of the best practices, it also provided uniform information, flexible planning, automatic execution, and inventory management.

These improvements translated into quantifiable business impacts. The first area was around operational safety as measured by reduced numbers of spills, tank overfills, and safety, health, and environmental (SHE) regulatory compliance issues.

Operational efficiency was improved by 30% as measured by jetty occupation time, truck turnaround time, and serial-to-parallel movements for receipts and deliveries.

The biggest impact on the business was in customer satisfaction as measured by operational transparency, increased service flexibility, and reduced contamination, claims/demurrage. One measure cited was a 20% reduction in paperwork, which typically goes with manual, delay-filled processes.

The lessons learned in fostering and implementing change over time was to align the plans with internal processes including those within Vopak, the EPC/consultants, and the automation supplier.

Here’s where you can find out more about Emerson technologies and best practices in terminal automation.

| iTunes