Douglas Morris

Director of Marketing, Mining & Power Industries

Wireless measurement devices are nothing new and installations are in just about every industry, including power. From my experience, power plants don’t choose to use wireless technologies to replace wired devices, rather they are used to solve some of those monitoring applications where the cost of laying copper is simply too expensive.

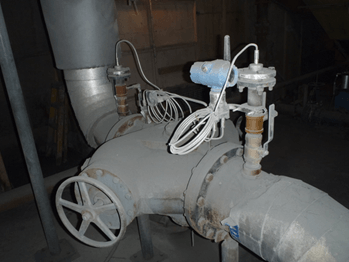

Those utilities that have deployed the technology in monitoring applications have found the additional data helpful to operations. One customer had a problem with strainers clogging on raw water intake piping and used wireless pressure transmitters to detect plugging.

This simple measurement prevented a constant maintenance problem. Another plant uses wireless devices as a means to better manage ash ponds and gain early insight into any changes at these ponds. Still others are using acoustic devices to track leakage from steam traps and relief valves. What users are finding is that the technology is very robust and that once a wireless system is in their plant, it’s easy to identify and add incremental monitoring points.

Rosemount 708 Wireless Acoustic Transmitter YouTube video (1:59):

Sometimes the power industry waits until other industries have proven a given technology. Well that time has come and the industry is now seeing the benefits of adding monitoring points that were previously not economical. It will be interesting to see the growth of wireless in power as more and more users accept and install this useful technology.