Robert Ferris, Ph.D.

Strategic Planner

Nanotechnology-enabled products are offering real value in equipment reliability

Reliability is the hot-topic in the automation world right now. Nearly every major company, ranging from BHP Billiton, BP, or BASF, has identified process reliability as essential for long-term productivity and profitability. Everybody wins when you improve plant reliability; there is increased production, safety, and lower operating costs. This means more revenue, more margin, and happier workers. Isn’t that nice.

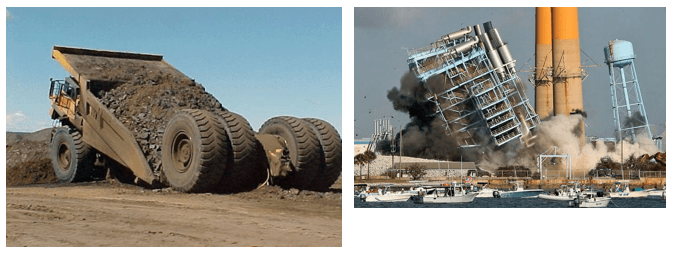

Figure 1. Reliability is both a production a safety concern. (photo1 link, photo 2 link)

Reliability, however, is a hard fought battle to gain sustainable improvements. Usually a step change in reliability requires a systematic change in how the plant operates, including; cross-disciplinary initiatives, operation practices, maintenance scheduling, inventory management, documentation, and even equipment suppliers.

Nanotechnology is also answering the reliability challenge with a range of industrial solutions including; longer-lasting materials, advanced coatings, and innovative sensing solutions. Below is a quick review of a few nanotechnology-enabled solutions that can improve equipment and process reliability.

From the simplest perspective, equipment reliability issues result from material wear. Over time, material wear results in abnormal operational behavior. Examples of material degradation affecting performance include the changing shape of a turbine blade, the thinning of a boiler wall, or the failure of a mining haul truck axle. (see figure 1) The bottom line is that things fail because they wear out. Therefore, the most obvious solution is to make your equipment out of something more durable.

As such, nanotechnology is delivering better alloys, plastics, and ceramics that resist wear and degradation. For example, integration of nanomaterial-based additives into established bulk materials can result in materials that resist degradation longer or out perform in more extreme environments.

A number of carbon-based nanomaterial providers are providing carbon nanotubes or nanodiamond additives (see Carbodeon and Ray Techniques Ltd) to enhance material longevity. TeroMatec® Nanoalloy 395N is revolutionizing welding using nanomaterial additives, which some would not expect in such an established trade. Also, many advanced alloys integrate one or more rare-earth metals (such as Lanthanum, Erbium, or Neodymium). For example, American Elements provides high-purity alloys to a number of industries for subsequent manufacturing. Nanotechnology is enabling the next generation of advanced materials by controlling the macro crystalline structure with atomic precision. Eventually, nanotechnology will pave the way for large scale offering of high-entropy alloys (HEA), such as AlCoCrFeNi0.5Ti0.5, that offers high yield stress and fracture strength.

Another way to improve material performance over time is protect it an adhesive coating or lubricant. This approach enhances the performance without significant change in equipment manufacturing or design. For example, Nanotech Coatings provides advanced UV protective coatings for metals, woods, and composite surfaces. NanoMech has developed a number of industrial solutions for extending the life of cutting blades (TuffTek®). TuffTek® introduces ultra-hard polycrystalline cubic boron nitride nanoparticles to protect the cutting blade during operation.

Nanotechnology is enabling improved lubrication oils that improve equipment performance and reduce wear. Products such as nGlide® by NanoMech and BORpower® by Novapro Technology are premium high-tech lubricant that reduces friction and abrasion during equipment operation. Alternatively, smart nanoparticle integration into lubricants can enable adaptive surface properties. Responsive lubricants can change their performance characteristics based on changes in the surrounding environment. One example of this is ApNano has developed a dual-acting continuous surface reconditioning lubricant additive that has been shown to improve time between failures and reduce equipment wear (Figure 2).

Figure 2. ApNano’s NanoLub® lubricant additive has been shown to improve equipment reliability through reducing wear during operation. (image link)

Automation providers are constantly looking for new sensing applications to improve operational insights. Sensor technologies are being deployed to monitor and predict equipment failure. Advanced sensing applications are also being developed to provide real-time corrosion monitoring solutions to operation managers. For example, Permasense has developed an RFID solution for pipeline and rank corrosion monitoring. (see figure 3) The Permasense solution has recently been implemented by BP in Cherry Point, Washington. Nanotechnology is also delivering advanced sensing technology to the automation space. To advance RFID tag development, Vorbeck Materials has developed a roll-to-Roll printing process for graphene-based RFID tags. A number of fiber-optic and strain nanosensors are also in development which will decrease power consumption and production cost.

Figure 3. The Permasense systems are installed corrosion monitoring solutions, designed to operate without maintenance for years in inhospitable environments. (image link)

Looking through the lens of reliability, you see how nanotechnology is not a single innovation but a broad-reaching technology revolution. Nanotechnology innovation enables systemic improvements in both products and their application.

Stay tuned: My next post will cover the energy cost of nanotechnology. All this innovation doesn’t come free!!

Robert Ferris, Ph.D. is a strategic planner with Emerson Process Managements. He holds a bachelors and masters in chemical engineering, an MBA in new technology commercialization, and a Ph.D. in Mechanical Engineering and Materials Science. He has an extensive background in nanotechnology development and advanced process control.

Please, share your opinion or questions! Reply below to provide your thoughts, insights, or comments with the experts.