Emerson’s Ken Planchard and Will Goetz presented Business Justification for Maintenance & Reliability Readiness at the Emerson Exchange conference in Denver. Here is their presentation’s abstract:

Many organizations today do not think of Reliability as a business strategy. Executives require business cases for implementing any program, and it can be difficult for maintenance and reliability practitioners to build one. Designing for Maintenance and Reliability Readiness (M&RR) during capital projects can increase profitability upwards of $500Million in the first 5 years of operation as well as save over $23Million during construction. This presentation builds the business case for including M&RR during capital projects and discusses how to overcome objections from project leadership.

Will opened noting how executives require business cases for implementing any program. Many organizations today do not think of Reliability as a business strategy. Business cases must have both capital project and operational benefits, be substantial, and overcome status quo objections.

Reliability is a business strategy since it impacts availability, costs and safety. For top performers, it provides a competitive advantage among its peers.

For new facility projects, maintenance and reliability readiness saves money on capital project costs, increases return on assets and integrates well into traditional EPC and main automation contractor (MAC) projects.

There is a strong business case for reliability programs for existing assets in increasing overall equipment effectiveness, increasing work process efficiency and helping appropriately scale warehouse inventories.

An effective reliability program increases shareholder value by reducing safety incidents, increasing availability and reducing maintenance costs. For capital projects, project costs are reduces and schedule and project risk is minimized.

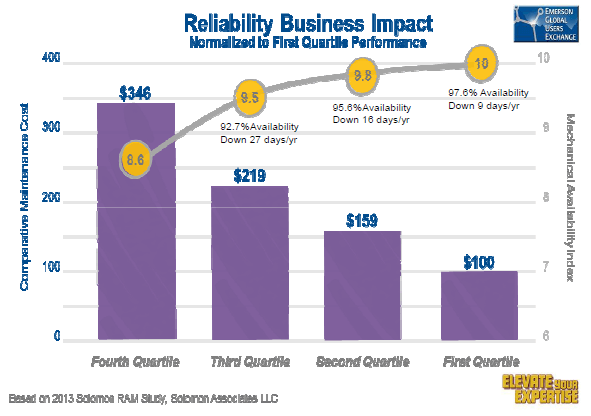

A 2013 Solomon study, improved reliability significantly reduces maintenance costs while increasing process availability.

Ken shared an example of an LNG facility designing for 94% availability was designing for 3rd quartile performance. If they designed for first quartile the profitability increases by $50million on revenues of $2Billion in sales annually.

He shared another example where optimizing spares inventory based on failure rates and criticality could reduce capital spend of $22M and annual maintenance spend of $40M based on $1B replacement asset value (RAV). This again is for the difference between 3rd quartile and 1st quartile performers.

From a capital project perspective, Ken noted that facilities are not typically designed with reliability programs in mind due to history and the separation between projects and ongoing operations. When a facility is not designed for a Reliability program, the result is significant start-up issues. And, after start-up if not properly addressed, the resulting impact can significantly affect the return on assets and the operations for years.

Ken shared a brownfield chemical plant case study where they were inconsistently producing at 55% nameplate (unlimited market) with an annual maintenance spend of 7% of RAV. ($8+ million).

By implementing reliability best practices including assessments, CMMS revitalization, work management, criticality ranking, maintenance strategy development, problem elimination, material management and predictive maintenance practices.

After one year implementing this program annual maintenance spend was reduced to 4% and produced at 130% nameplate.

Here is where you can learn more about justifying and establishing 1st quartile performance in reliability.