It’s likely that you have all the measurement instrumentation devices you need to safely and reliably operate your process manufacturing or producing facility. But perhaps you don’t have all the measurements you need for non-process control/process safety applications such as an energy management program.

Mark Menezes

Measurement Business Manager

He opens sharing the story of a Canadian power producer, SaskPower who:

…decided they required more than 200 new pressure, temperature and flow measurements to maximize energy efficiency at their plant in Saskatchewan, Canada. Adding these new measurements using traditional field wiring was deemed too costly in cash, time and physical space. Too, the existing control system could not handle additional inputs without significant (expensive) upgrades. Instead, SaskPower used WirelessHART® transmitters.

Mark noted that prior to wireless technologies, new measurements for energy management or other application would be wired to the control system using the HART digital communications protocol. The HART protocol is used in more than 80% of the smart devices shipped from more than 200 instrumentation suppliers.

WirelessHART, release in HART Revision 7:

…was approved in 2010 and became international standard IEC-62591. WirelessHART is backward compatible with (wired) HART, allowing the user to leverage existing tools and familiarity.

Since these wireless devices are not powered through incoming wiring, they use batteries. Communications frequency impacts the life of these batteries.

Although devices can be configured to update as fast as once per second, fast update rates reduce battery life. Since their measurements were intended for monitoring rather than closed loop control, SaskPower chose to update most measurements once per minute. At this rate, the supplied batteries are expected to last more than 5 years.

Multiple process measurements can also be transmitted, via a radio that can:

…communicate any number of signals, including multiple variables, diagnostics and configuration.

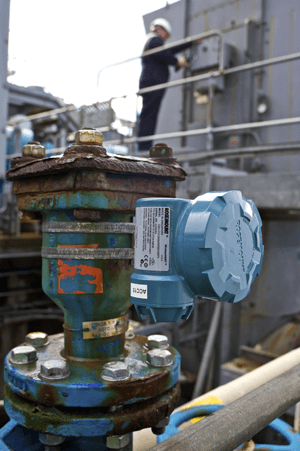

Emerson’s Rosemount 708 wireless acoustic transmitters help identify failed steam traps, leaking valves and boiler tube leaks at Barking Power in the UK

Most users find that the continuous diagnosis is not only faster but more reliable than manual testing, since steam traps usually fail intermittently over months—which might not be detected by a manual inspection—before failing completely. Similarly, relief valves can pop open for a few seconds or minutes, then close, which might not be detected by an operator.

Mark highlighted many operational and maintenance-related improvements opened up by the additional measurements. A few of these include quantifying gaps between potential and actual heat rate in real time, identifying equipment degradation early, finding stuck valves, and detecting steam leaks.

Mark concluded:

The WirelessHART system has succeeded in cost-effectively providing reliable real time measures and historical trends of actual performance of each unit. This allows SaskPower to improve energy efficiency and uptime today, and to make better long-term decisions. By comparing actual to potential performance, the company can better decide where to invest capital, and quantify the return on each investment as it’s made.

You can connect and interact with other wireless experts in the Wireless group in the Emerson Exchange 365 community.