You can hardly connect online without coming across articles about big data. Businesses are grappling with how to use this information to improve their businesses—from upfront marketing and sales through improving the efficiency of the supply chain and optimizing lifecycle support.

Emerson’s Jonathan Lustri shared background with me of how he is collaborating with a cross section of pharmaceutical and biopharmaceutical manufacturing customers to discuss challenges unique to these Life Sciences industries. The group meets via web conferencing on a monthly basis to share challenges and identify best practices. The group also meets face-to-face periodically. The next Life Sciences Symposium where the team will meet in person is April 14-16.The goal is to help shape tomorrow’s manufacturing facilities via process intelligence and analytics. The process starts with understanding common challenges which can range from organization bandwidth and readiness to rationalizing various projects underway to avoid disconnected solution silos to name just a few.

Based on some of the identified challenges, Jonathan noted specific areas where the use data and information could help to improve end-to-end supply chain operations:

- Ensuring proper receipt of proper raw materials

- Improving delivery of drug products to the patient

- Increasing capacity utilization

- Reducing cost of goods sold

- Reducing product release time

- Reducing time to market, improving quality, and assuring compliance.

- Increasing process understanding

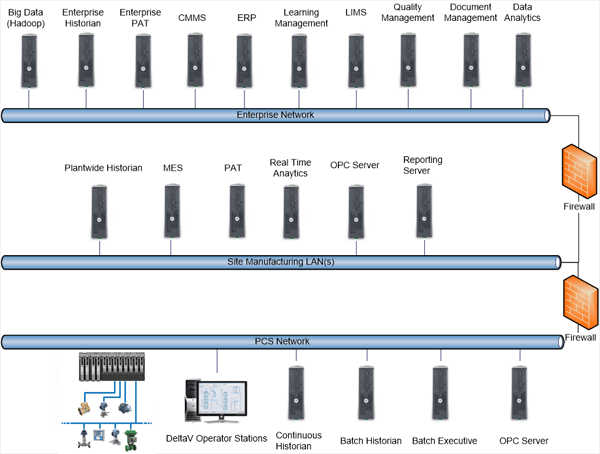

The output from discussions in these areas include the development of guidance & best practices around system architectures, project implementations and IT systems management. Case studies based up the application of these best practices are shared among the team. The other key part of this process is to identify potential technology improvements across the manufacturing IT architecture for investment by Emerson and other suppliers.

Areas of this manufacturing IT architecture to explore include batch automation, electronic batch records, multivariate data modeling, production management & scheduling, process analytical technology, statistical quality control (SQC); statistical process control (SPC), overall equipment efficiency (OEE), laboratory information management, process history, knowledge management systems (big data, search….), and training management systems.

This team is has shared many best practices and has been working on ways to benchmark and realize the return on investments and ways to deploy and train resources to sustain the investments over time.

You can connect and interact with pharmaceutical and biopharmaceutical experts in the Life Sciences group in the Emerson Exchange 365 community.