Emerson’s Eric Beltz and Shelby Traverso teamed up on an Emerson Exchange presentation, Enhanced Oil Recovery Improved with Wireless Conditioning Orifice Technology. Here is their presentation abstract:

A Middle Eastern petroleum company has improved its enhanced oil recovery by replacing its cone meters with wireless conditioning orifice technology. Steam Injection is a principal enhanced oil recovery tactic and commonly uses cone measurement systems to monitor its steam flow. Such systems required impulse tubing, steam pots, remote temperature sensors, multiple transmitters, and radios, which were found to be costly to install and maintain. By implementing wireless conditioning orifice flowmeters, the company has reduced install and maintenance costs and minimized construction delays.

Eric opened with an overview of the steam injection method for heavy oil recovery. The process involves injection, soak and extraction. The steam adds temperature and pressure to reduce viscosity and lift oil. Typically 5 injection wells are present for every one producing oil well.

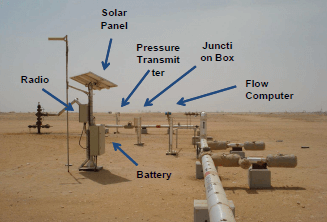

Eric described past injection methods. It included cone meters, steam pots, impulse tubing, remote thermowell, four transmitters – DP, P, T, and T, and a solar-powered radio.

Eric described past injection methods. It included cone meters, steam pots, impulse tubing, remote thermowell, four transmitters – DP, P, T, and T, and a solar-powered radio.

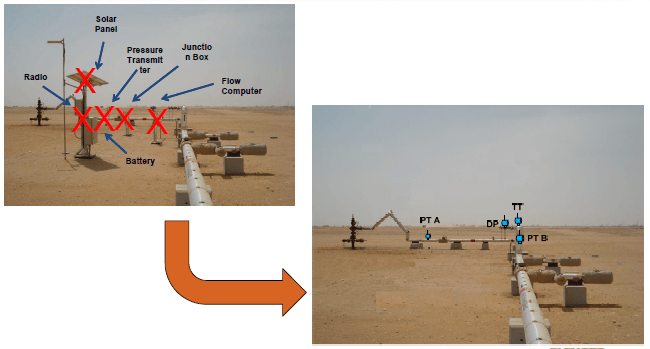

Advancements in differential pressure (DP) measurement technology with reduced piping requirements, reduced installation costs, improved performance, eliminated impulse lines and wireless-enabled transmitters.

In this desert environment, the wireless DP flowmeters provided a 75% installation savings over wired options, 10-year battery life and live trending which replaced manual readings done in the past. Since the flow rates did not change often the wireless update rates were set at one minute updates.

Using wireless devices significantly reduced the installation time and complexity:

Shelby noted that installation time for a wellhead was reduced from three days to do one to one day to do three wellheads.

The solution included compact conditioning orifice plates, direct mount and remote mount options rated at 900# and 7 valve head solutions.

Shelby summed up the benefits of the new design with improved DP measurement and wireless instrumentation:

- Reduced installation and maintenance cost

- Elimination of sand coated solar panels

- Reduced leak points

- Reduced maintenance and construction delays

- Integrated flow solution