In an earlier post, Avoiding Cold Climate Measurement Challenges, we mentioned a thermal range expander for differential pressure (DP) level measurement, which can be applied in application with higher process temperatures and lower ambient temperatures.

Josh Hernandez

Global Marketing Engineer

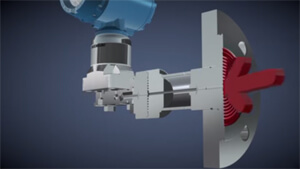

The video describes how the new Rosemount 3051S Thermal Range Expander helps to provide accurate and reliable process level measurement for applications with extremely hot process temperatures.

To accomplish this it uses two fill fluids within a single remote seal, which eliminates the need for heat tracing. This heat tracing has high installation, operating and maintenance costs.

The operating temperature of the remote seal is dictated by the fill fluid used. The use of two fill fluids allow each to operate in an optimal temperature range to minimize the impact of low ambient temperatures.

The two fill fluids are separated by an intermediate diaphragm with the high temperature fill fluid is next to the hot process side of the diaphragm and secondary fill fluid is selected for the wider ambient range of temperatures.

The pressure from the process is transferred from the primary fill fluid against this diaphragm to an intermediate diaphragm and across the secondary fill fluid where it is read by the pressure sensor and sent by the transmitter to the control system.

The pressure from the process is transferred from the primary fill fluid against this diaphragm to an intermediate diaphragm and across the secondary fill fluid where it is read by the pressure sensor and sent by the transmitter to the control system.

This thermal range expander technology is available in multiple configurations including direct mount or remote mount with capillary tubing and DP technologies including Rosemount 3051S Electronic Remote Sensor (ERS™) systems, Tuned-System™ Assemblies and balanced systems.

A balanced system is a symmetrical system that has the same seal and equal amount of capillary on the high and low pressure sides. Since the capillary lengths are the same, each side ideally has the same amount of fill fluid, minimizing or completely eliminating the seal temperature effect due to equal pressure on both sides of the transmitter diaphragm. The balanced systems are still affected by the head pressure.

Tuned-Systems Assemblies are asymmetrical systems with one seal directly mounted and another seal connected via capillary. Another possible Tuned-System Assembly is any remote seal system with unequal lengths of capillary or two different remote seals on the high and low pressure connections. Due to the unequal lengths of capillary, there are seal temperature effects. However, this seal temperature effect counters the head pressure from the oil-filled capillary and reduces total temperature effects on the entire system.

To connect and interact with other level measurement experts, join the Level group in the Emerson Exchange 365 community.