The Internet of Things and the Industrial Internet of Things (IIoT) are getting quite a bit of focus in the press and analyst community within our world of process manufacturing. The promise to be able to improve reliability, efficiency, safety and overall performance is compelling with the addition of sensors, analytical tools and work processes that can span the globe.

The promise and the ideas are big, but how do process manufacturers and producers get started and develop their IIoT strategies?

Emerson’s Jonas Berge tackles this question with his presentation, Modernize your plant with IIoT at your own pace, which he will give twice at the October 24-28 Emerson Exchange conference in Austin, Texas. Here is the abstract of Jonas’ presentation:Industrial Internet of Things (IIoT) enables richer process and asset data for more effective operation. You can modernize your plant with IIoT without replacing the DCS [distributed control system]. This session teaches how to get started to take advantage of new networked sensors and analytics software. Take a phased approach to implementation; start within the plant, only connecting to the Internet for cloud and Remote Monitoring Services much later; in 6 steps. 5 real world installations from different process industries and business models are summarized to provide guidance and savings indication.

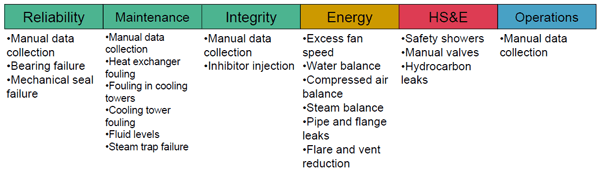

If you attend one of Jonas’ two workshops at the conference, he’ll share some of the challenges that an IIoT deployment can address, how it helps operations and what operational improvement results from what other plants have experienced. From his presentation, here are some example applications.

Jonas will build on his thoughts from a Control Engineering Asia article with the same title. In the phased approach he outlines, it begins with establishing a plant-wide digital sensor network with wireless and fieldbus based field devices to measure data collected manually or not at all. This data is typically outside the scope of the original control strategy but important for asset condition monitoring or energy management.

With a digital sensor network established, plant assets can be more easily instrumented for continuous monitoring. Analytical tools can then be added to identify and fix problems before they lead to abnormal situations. The next steps include:

- Reviewing work processes

- Enabling private IntRAnet of Things within the enterprise

- Enable IntERnet of Things with Remote Monitoring service business models by third-party experts

He will share examples from installations that have received business results including optimized use of personnel, steam consumption reductions, and improved analyzer management.

I look forward to seeing you in Austin next month. You can register by September 30 and save $200 off the conference registration fee. You can also connect and interact with other wireless and technology experts in the Wireless group in the Emerson Exchange 365 community.