The NAMUR (User Association of Automation Technology in Process Industries) is:

…an international association of user companies (established in 1949) and represents their interests concerning automation technology. NAMUR numbers over 140 member companies.

NAMUR working groups exchange experiences to develop recommendations. One of the recommendations of the Modular Automation Working Group is NE Recommendation 148 – Module-Based Production in the Process Industry – Effects on Automation in the “Industrie 4.0” Environment. Here’s the NE 148 abstract:

With the aim of a substantial time reduction between idea and product launch, process engineering develops new designs for chemical plants, using modular components. These end up in the capability of “plug and produce” plant components increasing the flexibility and shortening the project duration. The purpose of this NAMUR recommendation is the support for automation over the life-cycle in modular designed plants.

At the Emerson Exchange conference in Austin, Emerson’s Klaus Erni presented NAMUR Recommendation 148 – How the modularization of Process Plants should work in the near future. His abstract:During the last decades, a lot of standards for traditionally designed plants were created. Within the process industry modular plant design and its standardisation have just started. The introduction of modular composed process plants must not be slowed down by insufficient automation technology. Instead, the automation is supposed to be a driver and innovator. Furthermore, many of the required developments can become a competitive advantage in traditional installations. The NE 148 provides a respective frame for automation in modular designed plants.

This presentation will discuss in detail how the NAMUR Recommendation 148 see’s the modularization of Process Plants coming together in the near future. The NAMUR Group is the User Association for Automation in Process Industries. Emerson is represented in the Working Group of the ZVEI Automation Division. ZVEI is the German Electrical and Electronic Manufacturers’ Association. As some specifications were completed recently, it’s time to share and discuss them with a wider spread audience. The goal of this session is to share insights and receive feedbacks from users out of Europe.

Klaus opened the presentation noting that NE 148 defines how modular plant construction should work in the near future, by interconnecting modules (skids) via an automation system backbone. This means that in addition to signal integration, the operation of modules, diagnostic support and engineering through a uniform system will be enabled. Batch automation and manufacturing execution system (MES) level incorporation into the backbone will be included. Should this standard be adopted, it could potentially solve many of today’s existing skid integration issues.

Today, there are no standardized protocols, data formats, human machine interface-related content, etc. for skid integration. This means that project teams often must perform a lot of rework which is time consuming and labor intensive and not flexible to project changes. NE 148 defines a vendor neutral description language called MTP (Module Type Package). This covers the data integration into the process management level, PFE (Prozess Führungs- Ebene)—the backbone of the automation system. Implementing this standard requires automation suppliers to develop MTP export and import engineering tools to convert these descriptions into the native control and operating configurations inside the automation system.

He noted that the standard makes several assumptions:

- Automation concept based on decentralized Intelligence residing in the Modules (Package Units)

- The Module itself is operating in an intrinsically safe way (totally self-controlled)

- There will not be a 100% working solution when introduced

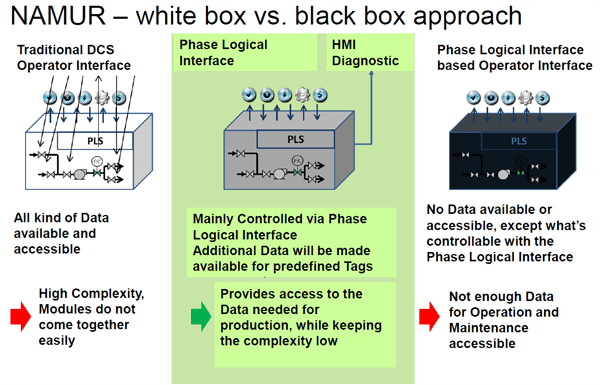

- Automation will be driven from a “white box” approach towards a “black box” approach

Here is a contrast of the white and black box approach:

In subsequent posts, we’ll show how MTP enables project & system independent module engineering, pros & cons of this approach, future enhancements to the NE 148 standard, some data definitions for data exchange, diagnostics, HMI representations, phase logic and how these could work in the DeltaV system and Syncade MES suite of software.

You can connect and interact with other control system experts in the DeltaV group in the Emerson Exchange 365 community.