Factories and production processes are commonly built by installing many subsystems and standalone machines. Integrating the automation among so many elements can be complex and expensive. Fortunately, PLC and PAC automation technology has improved in many ways, moving us toward a reality where individual and modular subsystems can be self-assembled into a greater whole.

For the July 2020 issue of Control Engineering, I wrote an article titled Moving Toward Self-Assembly Machine Automation Systems, which discusses the concepts and technologies for attaining this goal.

Defining Automation Self-Assembly

Even though it is common for processes and packaged equipment to be automated with PLCs and PACs, it can be uncommon for them to “play well” together. Various automation platforms, programming practices, communication protocols, and even intellectual property concerns mean many such subsystems are not “plug and play”.

However, if each subsystem could define the available data and functionality, and then expose these attributes to other systems, it would make system integration efforts more efficient.

This ability can be referred to as self-assembly, and it leads to simpler, less costly, and quicker implementations.

Integration Evolved

Self-assembly relies of several PLC and PAC features which have been advancing over the years.

Programing and Data Modularity

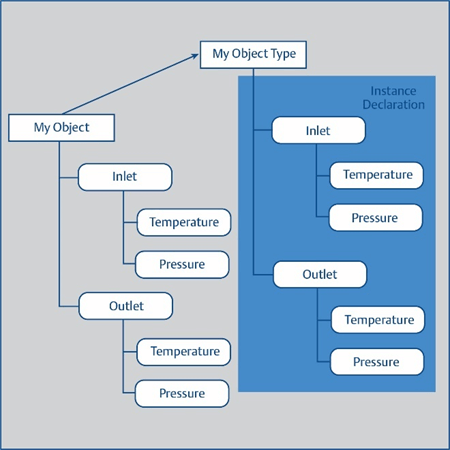

These concepts make it possible to create a library of standard code objects promoting the creation, use, improvement, and re-use of code and data structures.

Industrial Ethernet

Ethernet has become the networking method of choice, and there are also many industrial fieldbus protocols for specialized needs. Advanced Ethernet protocols like OPC UA include reference, variable, object, and data types so data models can be created with semantics. Semantics enhances the data with embedded context, also receiving systems to interpret it.

System-Level Modular Concepts

The preceding elements of logic and data encapsulation are building blocks for achieving an overarching machine-as-an-object (MaaO) concept. Machines designed using MaaO practices can effectively announce themselves and be integrated into other systems. Industry standards like NAMUR module type packages (MTP) are paving the way for developers to standardize equipment functionality and interfaces. Supervisory systems can import subsystem functionality, data exchanges, and even human-machine interface (HMI) graphics directly.

Path Toward Self-Assembly

Industrial automation has evolved along a path leading to better integration, using concepts like MaaO and MTP.

Forward-looking companies are ensuring their PLCs, PACs, edge controllers, software, and networking platforms are ready for self-assembly, providing end users with the ability to assemble and reconfigure production plants using modular subsystems.

Systems developed using self-assembly concepts simplify integration work, saving money and reducing risk.

Figures all courtesy of Emerson