Marcio Donnangelo and Marcelo Dultra presented on continuous pressure relief valve (PRV) and rupture disk (RD) monitoring for releases and leaks at the 4C Health, Safety & Environmental conference. Marcelo described a PRV. They are mechanical devices, disconnected from the control system that operate when a set pressure is exceeded. They should never operate in a normally running plant.

The traditional way to verify that a pressure relief valve is working is to do preventive maintenance on a periodic basis. Checking these is extremely labor intensive and these are typically installed in difficult to access spots such as the top of tanks. Accessing them may involve the use of cranes or scaffolding. Performing these maintenance practices often involve working in hazardous locations.

Marcelo cited a study with a U.S. refiner where 20% of the PRVs were leaking. Typical reasons for the leaks are that the PRV didn’t reseat properly after releasing. Or, debris may have gotten in the seat.

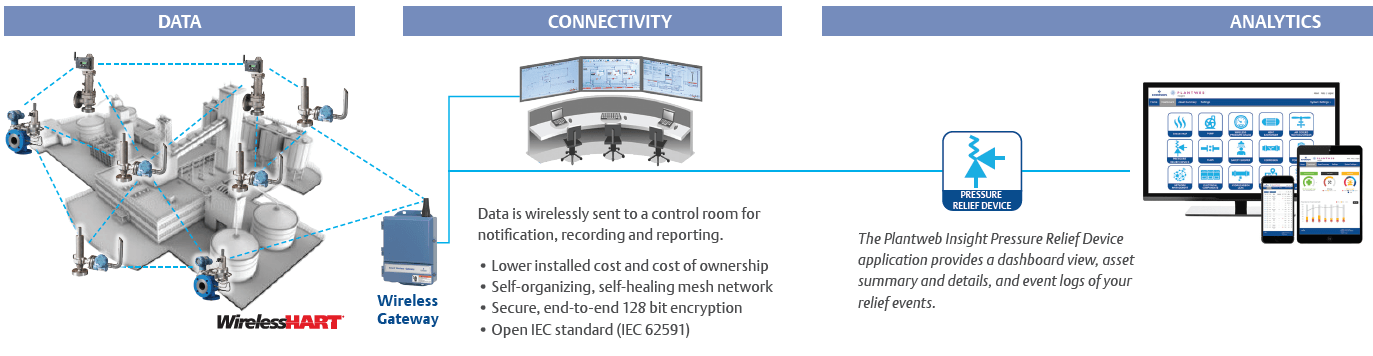

If you use wireless sensors to monitor these PRVs, you have the data to correlate what happened which likely caused the release. For instance, what were the surrounding pressures, flows, pH levels, etc. at the time of the release? The data from monitoring these devices also feed analytics packages, such as Plantweb Insight for PRVs. These operational analytics help identify where leaks are occurring, and which ones should be scheduled for maintenance. This information helps to optimize the schedule for a shutdown, turnaround or outage.

This monitoring improves regulatory compliance, safety, reliability, and reduces costs. From a compliance standpoint, continuous monitoring provides immediate notification of events which can be addressed to reduce the severity of the event. The releases are time-stamped with duration for compliance reporting.

Marcio described a flare application. Acoustic transmitters monitor downstream of the PRV to accurately identify any releases or leaks. All the PRVs and rupture disks that feed the flare system can be monitored to provide the data to determine the cause of the flare event.

Visit the Pressure Relief Valve Wireless Monitoring section on Emerson.com for more on solutions to improve the performance of your operations. You can also connect and interact with other PRV and RD experts in the Valves, Actuators & Regulators group in the Emerson Exchange 365 community.