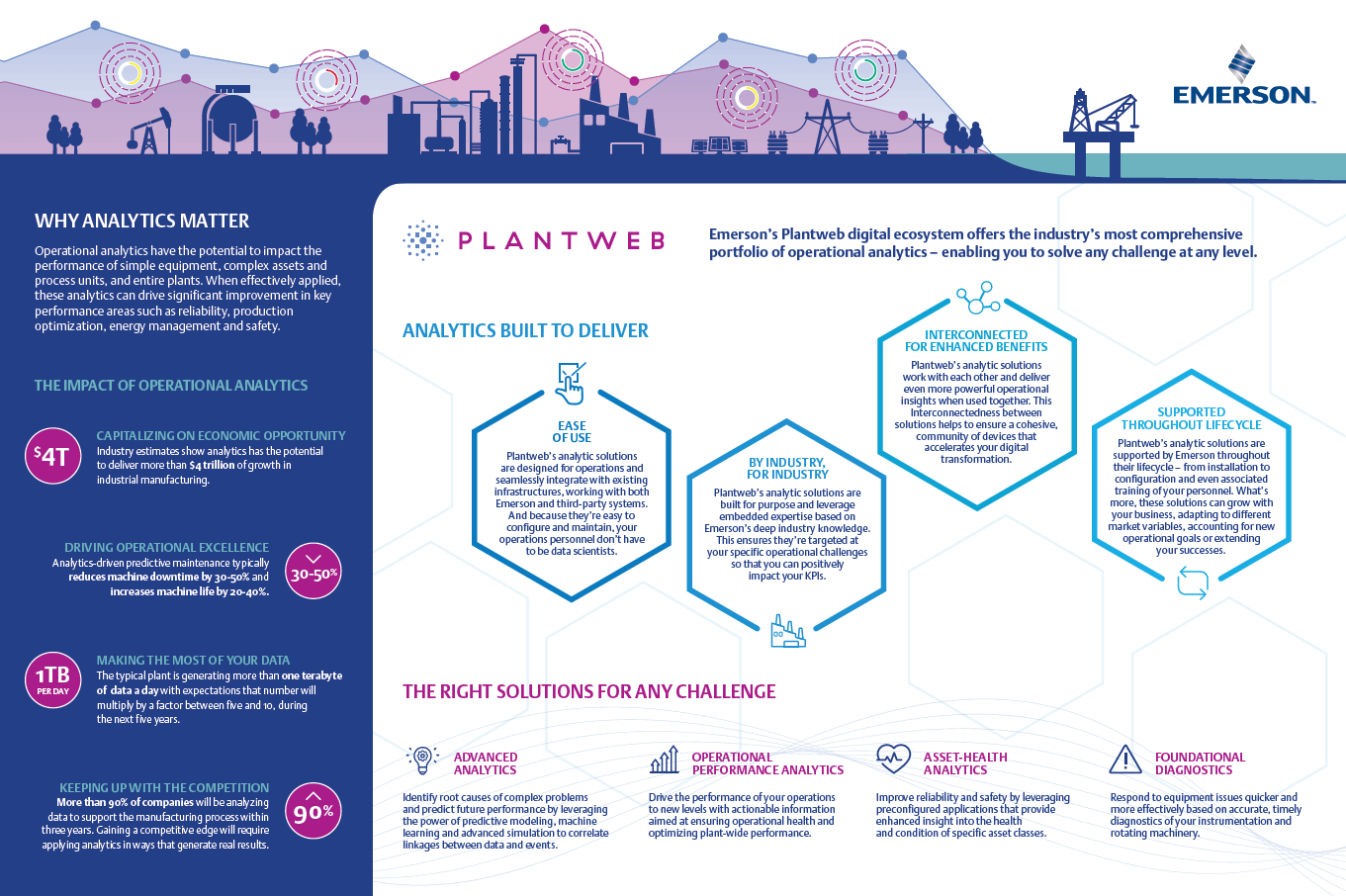

The Industrial Internet of Things (IIoT) has unleashed a torrent of data beyond what is captured and recorded by control and data acquisition systems. Wireless sensing technologies have expanded to monitor personnel safety, machine health, energy efficiency, and more. Operational analytics, the analytics focused on the production process, are critical in turning this wealth of data into actionable information for manufacturers and producers. Industry estimates show operational analytics has the potential to deliver more than $4 trillion of growth in global industrial manufacturing.

Operational analytics stand to make a significant impact on the operations of the companies who implement them, but achieving this impact depends on choosing the right, built-for-purpose analytics. It’s important to know which analytics to deploy. The more traditional type of analytics and the type of analytics in play when initially designing facilities and equipment are principles driven. These are rule-based models where we know things such as, “When this goes wrong, it generates this kind of symptom.”

The other is the data-driven analytics, where you’re building a model or predicting a behavior largely from statistical analysis of the data without knowing the actual mechanisms or physics about what’s going on. It is very important to let the problem you’re solving drive the technology. Apply the appropriate analytics at the appropriate level. Depending on your needs, a different mix of principles-driven and data-driven analytics is required.

A path to gain the business-critical insights that drive operational improvements is to work with a trusted supplier who offers a comprehensive portfolio of analytics–there are foundational diagnostics, asset-health analytics, operational performance analytics and advanced analytics. Clear business objectives and identification of key problems lead to effective solutions.

Important for productive maintenance programs, foundational analytics help you respond to equipment issues quicker and more effectively using foundational diagnostics of your instrumentation and rotating machinery. Asset-heath analytics help drive safety and reliability improvements by using preconfigured applications that provide enhanced insight into the health and condition of specific asset classes across your operation.

Operational-performance analytics drive plant and enterprise performance to higher levels using rich analytical tools that help ensure operational health and optimize performance. Advanced analytics based on artificial intelligence and machine learning technologies help you identify root causes of complex problems and predict future performance using analytics that leverage the power of predictive modeling and advanced simulation to correlate linkages between data and events.

Effective operational analytics solutions also need to be easy to use, built for purpose, interconnected for bigger benefits and supported throughout lifecycle. They should seamlessly integrate with your existing operational technology (OT) ecosystems and networking infrastructure and be built to scale up over time. When you have analytics that deliver these benefits, you’ll impact operational performance/gain and maintain a competitive edge–and accelerate your digital transformation with confidence, ease and speed.

Visit the Plantweb Optics section on Emerson.com for more on the software and solutions to enable you to link production data with back-office business, decision-making systems to unlock process data and drive efficiency and profitability for your operations. You can also connect and interact with other operational analytics experts in the IIoT & Digital Transformation group in the Emerson Exchange 365 community.