At the Emerson Exchange America’s Virtual Series, Emerson’s Adam Gibson discussed control of pick and place machines. Here is his presentation abstract:

Machine Safety is a key aspect in today’s Industrial Environment. This Pick and Place machine with advanced fieldbus control highlights zone safety in pneumatic systems. Additional IIOT capabilities like cylinder and valve monitoring and alert functions provide machine users basic analytics for improved machine performance and reduced downtime.

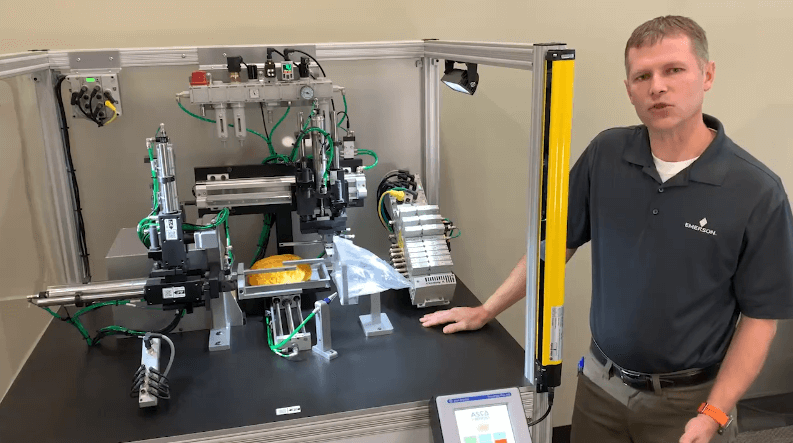

Adam opened showing the operation of the pick and pack machine showing all the sensors, controls, and safety functions involved in reliable and accurate control. The machine included pneumatic cylinders, valves and pneumatic valve manifold, pneumatic air supply regulation, I/O, and zoned safety shutdown light curtains.

Adam opened showing the operation of the pick and pack machine showing all the sensors, controls, and safety functions involved in reliable and accurate control. The machine included pneumatic cylinders, valves and pneumatic valve manifold, pneumatic air supply regulation, I/O, and zoned safety shutdown light curtains.

The valve manifold has Ethernet I/O communications and 16 I/O discrete and analog modules. This manifold and I/O can be widely distributed around the machine located by the sensors and pneumatic final control devices.

Adam showed the diagnostics that provide a visual display when a problem develops. These diagnostics can also be communicated through the digital communications back to the PLC or other control system. Cables can provide both power and communications to the I/O modules.

The AVENTICS G3 electronic fieldbus platform provide an embedded webserver to enable browser-based view of operating parameters, diagnostics, configuration, documentation and other information. He showed the view from the browser for the G3 device. It included an IP network communications configuration page, a diagnostics page to support troubleshooting operations. These diagnostics enable a deeper dive into individual modules to determine the problem in order to resolve the issue.

It allows programmable logic controllers to more efficiently turn valves on and off, and to channel I/O data from sensors, lights, relays, individual valves, or other I/O devices via various industrial networks. The G3 contains a graphical display used for configuration, commissioning, and diagnostics. It enables improvements in application, performance, and maintenance for original equipment manufacturers (OEMs) and end users alike.

Visit the Packaging and Fluid Control & Pneumatics sections on Emerson.com for more on these and other technologies for more safe, reliable and efficient machine operations.