At the 4C Health, Safety & Environmental conference, Emerson’s Meha Jha presented Validating the Data and Understanding the Uncertainty for Environmental Reporting. Here is her presentation abstract:

New sustainability programs are driving increased focus on environmental reporting requirements. We are going to discuss reporting challenges and measurement issues related to Green Diesel production, Energy & Emissions reductions and possible Carbon Capture in the future.

As technologies rapidly evolve in each of these sustainability areas, we continually learn and leverage lessons from other industries and world areas to understand the impact of regulations, and the importance of accurate and reliable data to support environmental objectives.

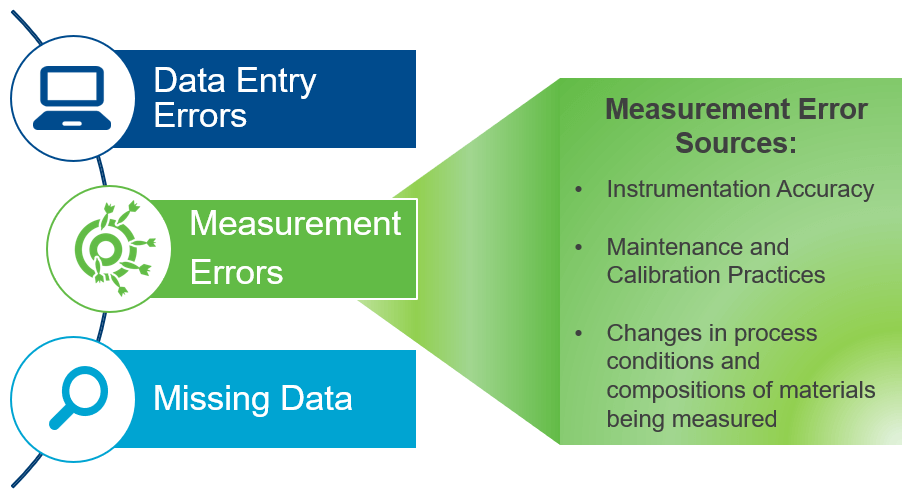

Understanding the uncertainty associated with field measurements, and validating the data used for environmental reporting will be a significant component to sustainability programs.

Meha opened discussing measuring and monitoring sustainability in refining in terms of refinery performance metrics, emissions management and renewable fuels. Refinery performance metrics from Solomon include their Energy Intensity Index (EII) for a refinery’s energy consumption. Some emissions managements measures include the EPA Refinery Sector Rule 40 CFR Part 63 Subpart CC flare monitoring, the Solomon Carbon Emissions Index (CEI), and carbon capture.

She described the Carbon Intensity (CI) Score. It’s how much carbon dioxide (CO2) or carbon dioxide equivalent (CO2-e) is emitted by the complete lifecycle of a fuel per unit of energy delivered. CI varies based on lifecycle factors and strongly influenced by energy efficiency based on feedstock selection, feedstock production, energy and process conversion into fuel.

She described the Carbon Intensity (CI) Score. It’s how much carbon dioxide (CO2) or carbon dioxide equivalent (CO2-e) is emitted by the complete lifecycle of a fuel per unit of energy delivered. CI varies based on lifecycle factors and strongly influenced by energy efficiency based on feedstock selection, feedstock production, energy and process conversion into fuel.

CI scores are a key factor in programs aimed at reducing pollution generated by transportation, namely the California Low Carbon Fuel Standard (LCFS) and Oregon Clean Fuels Program (CFP).

Measurements matter in LCFS reporting. Mass balance can be challenging especially with co-location facilities with measurements in hydrogen consumption, fuel gas consumption, chemical inputs, product and by-product yields, accuracy of all production, import and exports.

Energy and utilities consumption can be challenging with co-location facilities with natural gas, utilities such as electricity and steam, and transportation modes.

Meha described two flow measurement technologies—DP Orifice Flow and Coriolis mass flow measurement. DP flow measurement devices measure volumetric flow and require pressure and temperature compensation to address changes in volume. Coriolis flow measurement is more accurate since it measures mass flow and density and can calculate volumetric flow without pressure and temperature compensation.

Better measurements can improve the CI Score. CI varies based on lifecycle factors and strongly influenced by energy efficiency: feedstock selection, feedstock production, energy and process conversion into fuel.

Better measurements can improve the CI Score. CI varies based on lifecycle factors and strongly influenced by energy efficiency: feedstock selection, feedstock production, energy and process conversion into fuel.

Steam distribution measurements can also improve your CI Score. Some of the steam energy balance measurement technologies include steam flow measurement with vortex meters, compact conditioning orifice plates, integral DP meters for low volume steam flow, Annubar flow meters for high volume steam flow, SIL-certified vortex meters, multivariable DP flow compensation for steam, wireless DP flow measurements, and steam trap monitoring.

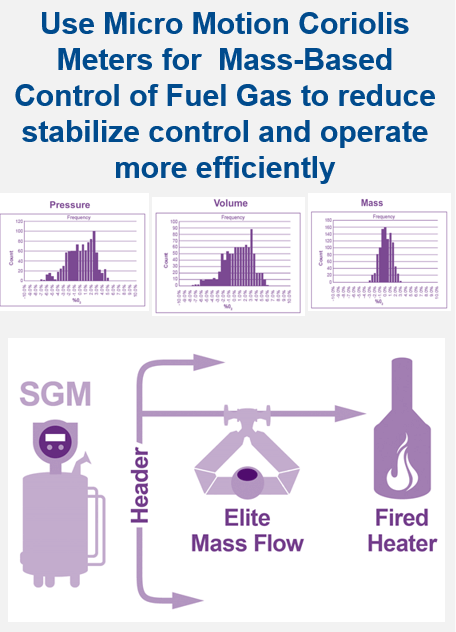

Combustion controls are improved with mass-based fuel gas flow measurements using Coriolis meters. Since fuel gas composition can vary, it results in different air requirements for combustion. The tendency is to operate with high excess air to prevent trips during fuel rich conditions but results in excess emissions and energy costs.

These better measurements improve safety by stabilizing fired heater operation and avoid trips during rich fuel conditions, increase energy efficiency and reduce NOx emissions by operating with less excess air, accurately and easily report fuel gas consumption for regulatory reporting, and handle load fluctuations with wide meter rangeability and turndown.

Visit the Flow Measurement section on Emerson.com for more on the flow measurement solutions to drive improvements in the validation of emissions reporting for more sustainable operations.