Failure to prevent overfills and leaks in storage tanks containing hazardous materials can have catastrophic consequences. By enabling containment areas to be continuously monitored, Emerson’s guided wave radar solution provides a vital extra safety layer.

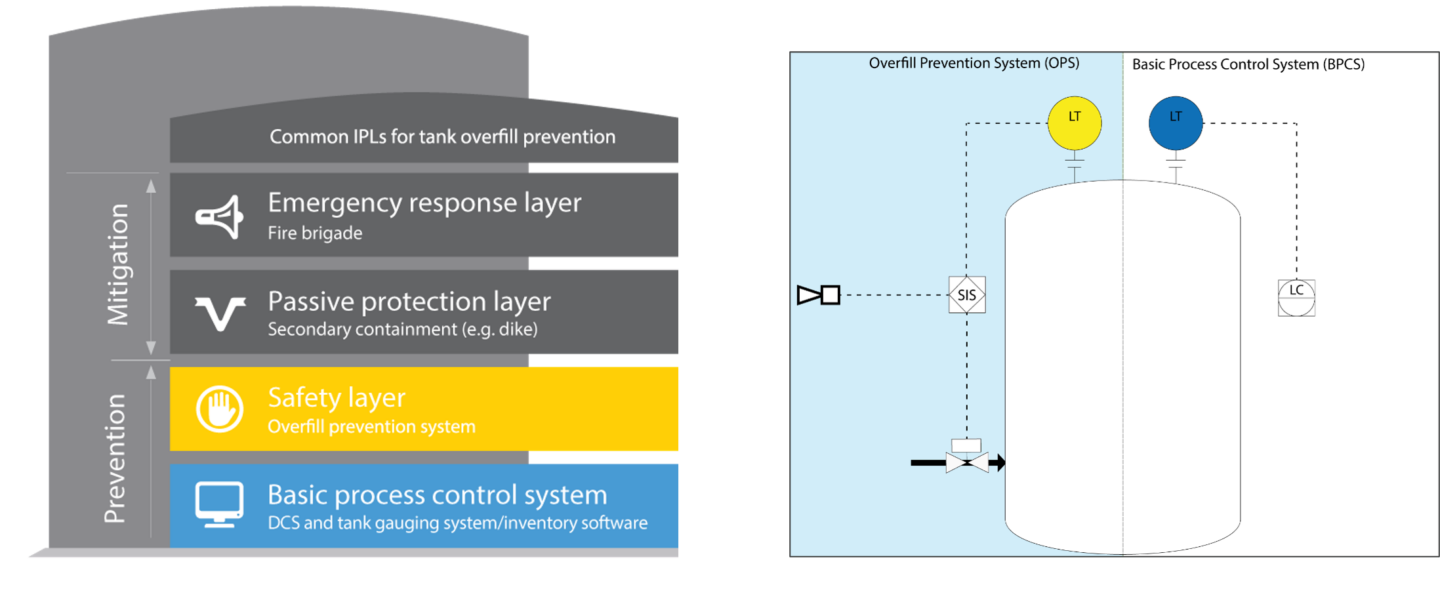

High-profile incidents such as the explosion and fire at the Buncefield oil storage terminal in the UK in 2005 demonstrate that failure to identify and prevent spills and leaks from large hydrocarbon storage tanks can have devastating consequences. Organizations must therefore implement robust safety measures that minimize risk and comply with the key global standards relating to overfill prevention: IEC 61511 and API 2350. Both these standards recognize the importance of employing a series of independent layers of protection.

Properly addressing the risk of spills and leaks requires employing a series of independent protection layers.

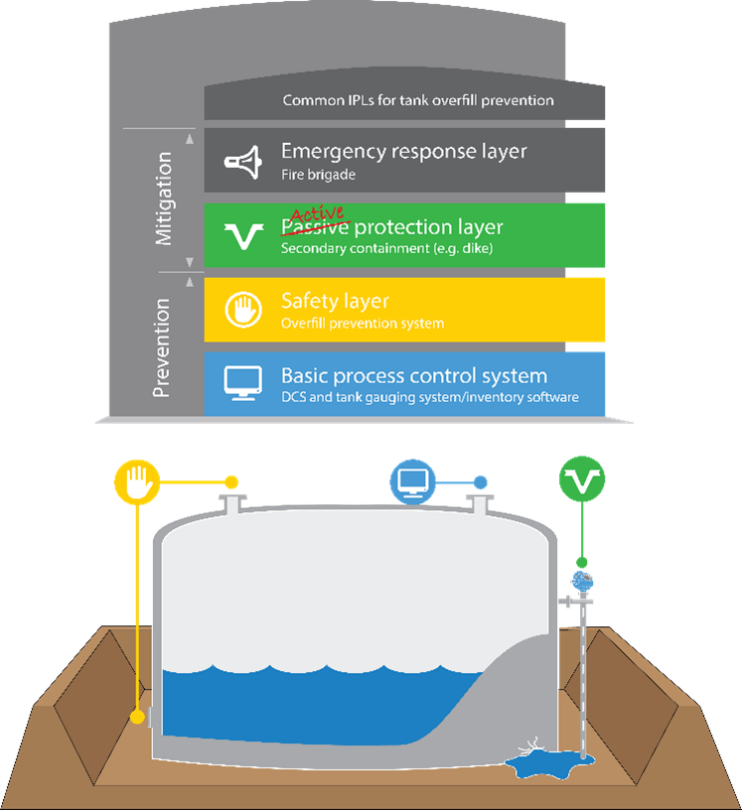

In a Chemical Processing article, ‘Continuous Level Monitoring Bolsters Safety’, Emerson business development managers Phil Lever and Jimmie Söderström focus on the layer of protection formed by containment areas. They explain how Emerson’s guided wave radar solution, the Rosemount™ 5300 Level Transmitter, enables continuous monitoring of what was previously a passive protection layer, thereby increasing safety, reducing emissions and minimizing pollution risk.

Phil and Jimmie explain that containment areas are typically an underground pit or dyke surrounding a tank, into which spilled or leaking liquid can accumulate to prevent it from spreading any further. This minimizes the consequences in the event of an overfill causing spillage, or from tank damage resulting in a leak. This is important because:

…When storage tanks are being filled and emptied daily, leaks often can go undetected given the huge volumes of product. However, even a small leak, over time, can lead to a substantial accumulation of hydrocarbons in the containment area.

Monitoring containment areas via visual inspection during manual rounds is time-consuming, places workers in hazardous areas, and can result in spills or leaks going unnoticed for some time. IEC 61511 and API 2350 cover overfill prevention measures inside tanks, but as Phil and Jimmie explain:

…no regulatory requirement forces companies to install level measurement instrumentation to detect spills and leaks through continuous monitoring of containment areas. Nevertheless, some organizations recognize the valuable safety benefits this additional layer of protection provides and require automated monitoring of containment areas at their sites.

Automated monitoring of containment areas makes this layer of protection active rather than passive.

The article describes how a global oil and gas company wanted to install continuous level monitoring in the containment areas around hydrocarbon storage tanks at its facility in Antwerp, Belgium. Seeking instrumentation that could detect leaks as quickly and reliably as possible, to increase site and personnel safety, the company initially installed hydrocarbon detecting sensors. However, these probes were not sufficiently robust, and short circuits regularly caused false fire alarms. As Phil and Jimmie explain, the company:

…sought alternatives from several leading automation technology vendors. Its requirements included the capability to cover the full containment area, to measure an interface between oil and water, and to detect hydrocarbons from a thickness of 60 mm. The technology also would have to be unaffected by weather changes in the containment area and be able to operate reliably whether the area was dry, contained one liquid (water or hydrocarbon), or two liquids (water and hydrocarbon, requiring both level and interface measurements).

After considering various proposals, the company bought 44 units of Emerson’s Rosemount 5300 Level Transmitter, which uses guided wave radar (GWR) technology, for use on all containment areas at the Antwerp site. Describing the benefits of GWR technology, Phil and Jimmie explain:

…In GWR technology, low energy microwave pulses are guided down a submerged probe. Microwaves reflected back to the transmitter from the surface enable level measurement. Because a proportion of the emitted pulse continues down the probe, the technology also can detect an interface, which makes it ideal for identifying the presence of oil as well as water in containment areas.

When GWR transmitters are used in interface level measurement applications, the upper liquid layer typically must be between 50 mm and 200 mm to enable the device to distinguish between the signals reflected from the two different liquids. With containment areas being so large, a considerable amount of hydrocarbon leakage could take place before a device identified it. Therefore, an important consideration for the company was detecting the presence of hydrocarbons in the containment area much sooner, and this was a key reason for the selection of the Rosemount 5300, as Phil and Jimmie explain:

…Its enhanced functionality permits reducing the minimum detectable thickness of the upper liquid to just 25 mm — thanks to Emerson’s Peak in Peak interface algorithm, which allows the transmitter to detect signal peaks that are closer together without having to decrease its signal bandwidth, which would reduce its high sensitivity.

The transmitters used at the Antwerp installation have a large coaxial probe with no internal spacers, to increase resilience against clogging. A dead zone at the very bottom of the probe typically limits the measuring range of GWR transmitters. However, a redesign of the large coaxial probe’s centering disk has minimized the lower dead zone in the Rosemount 5300 to just 20 mm for water and 50 mm for hydrocarbons — a 50% reduction from what was previously possible.

The Rosemount 5300 GWR level transmitter with a large coaxial probe provides robust level measurements with a much-reduced lower dead zone.

While the company already had an overfill prevention system in place, the automated continuous monitoring of the previously passive safety layer is providing greater visibility of potential leaks, which previously was not possible. Phil and Jimmie describe how:

…The ability to detect a very thin hydrocarbon layer enables quicker identification of leaks and, thus, doing necessary tank repairs and clean-up activities sooner. This, in turn, reduces emissions of volatile organic compounds, minimizes risk of soil and water pollution, and decreases the chance of a vapor cloud forming and spreading across the facility. In addition, use of automated monitoring means personnel no longer must visit hazardous areas to perform visual inspections and, instead, can focus on value-adding tasks.

Installing Rosemount 5300 GWR level transmitters to provide automated monitoring of containment areas provides greater visibility of potential leaks.

Following the success of the Antwerp facility solution, the company and Emerson are exploring further opportunities to introduce continuous level monitoring in containment areas at other sites globally.

To learn more about why the Rosemount 5300 Level Transmitter is an ideal solution for level and interface applications, visit Emerson.com/Rosemount5300. You can also connect and interact with level measurement experts in the Measurement Instrumentation group in the Emerson Exchange 365 community.