In the process and hybrid manufacturing and production industries, fluids flowing through piping can cause corrosion and erosion over time. In a 4C Health, Safety & Environmental Conference presentation, Corrosion & Erosion Relates to 56% of Losses with Piping. Overcoming These Challenges While Increasing Carbon Capture., Emerson’s Justin Vasquez described the challenges and solutions to address these conditions.

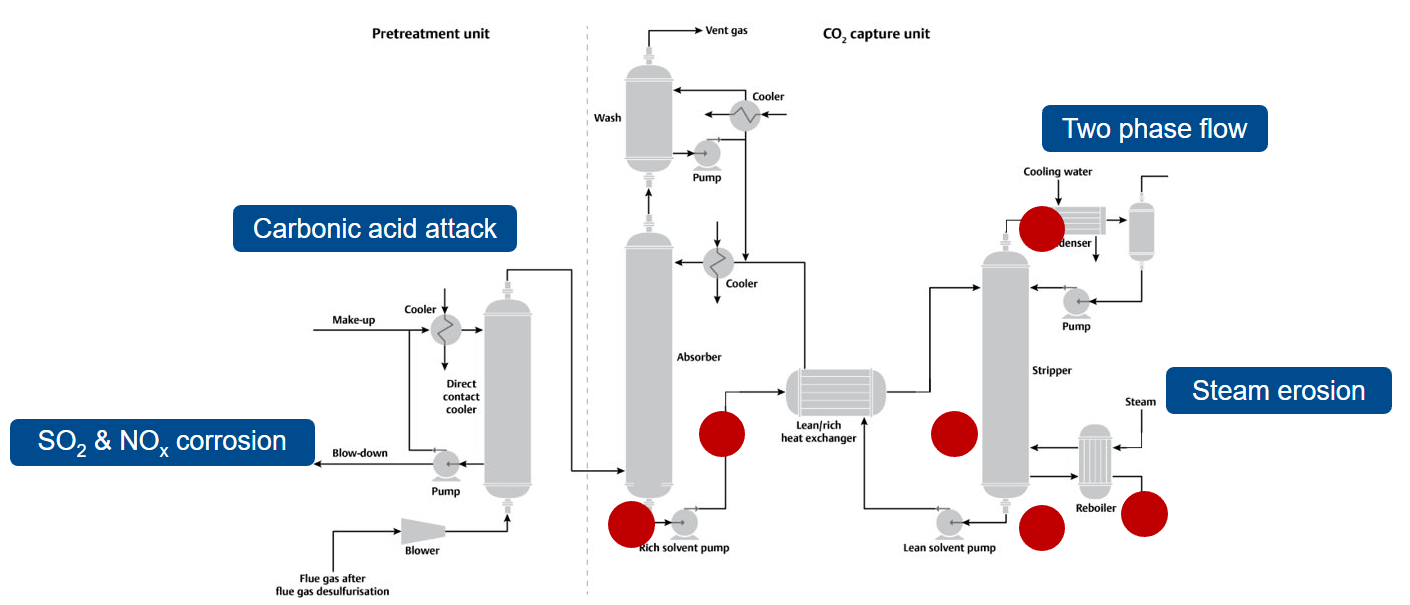

His presentation focused explicitly on carbon capture projects essential to sustainability initiatives in the upstream, midstream, and downstream hydrocarbon sectors. Justin explained that these projects can potentially remove 90-99% of a facility’s carbon emissions. In these carbon capture projects, amine absorption is one of two concern areas for corrosion and erosion.

Corrosion is the primary cause of CO2 pipeline failures, primarily from the liquefication phase. Removing water is essential in avoiding risk. The cost of corrosion-resistant piping is typically not economically viable, and traditional corrosion monitoring methods are unsuitable. Infrequent manual measurements often have poor repeatability and accuracy. Calculating corrosion rates is challenging and unreliable. Informed decision-making is difficult given these challenges.

Dense-phase CO2 leaks are violent and incredibly dangerous. Large sections of piping can be damaged with a crater created. This risk must be mitigated to protect personnel, the surrounding community, the environment, and the company’s financial viability.

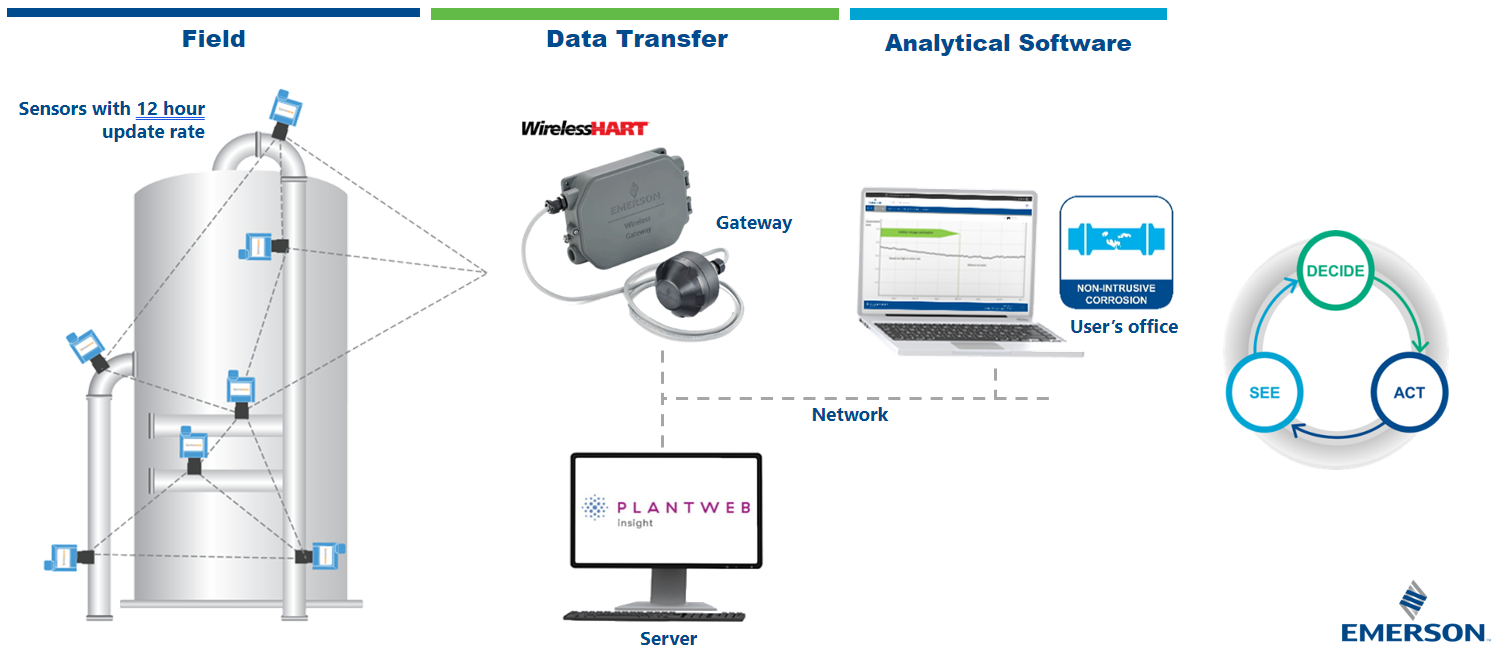

An effective solution to mitigate these risks is to install Rosemount Wireless Permasense Corrosion & Erosion transmitters for continuous, real-time measurements that feed built-for-purpose operational analytics in the Plantweb Insight Non-Intrusive Corrosion application. Data from these transmitters are delivered securely to the end user’s desk, providing visualizations and analytics to assess the impact of corrosion and erosion.

Follow the links above for more on these technologies to identify corrosion and erosion before it affects safe and sustainable operations.