In an earlier post, Connecting with Experts in the Spring Event Season, I highlighted one of Emerson’s Greg McMillan’s AIChE Spring meeting presentations, Control Valve Modeling and Control. I just heard from Greg that his paper/presentation was awarded the best in its category. Congratulations to Greg!

In addition to the link to the presentation above, here is the link to the Control Valve Modeling and Control paper. It’s a fascinating read of the challenges with control valve response in proportion-integral-derivative (PID) control loops.

Here are the 33 best practices from the paper that Greg offers:

- Use sizing software with physical properties for worst-case operating conditions

- Include effect of piping reducer factor on effective flow coefficient

- Select valve location and type to eliminate or reduce damage from flashing

- Preferably use a sliding stem valve (size permitting) to minimize backlash and stiction unless crevices and trim causes concerns about erosion, plugging, sanitation, or accumulation of solids particularly monomers that could polymerize and for single port valves install “flow to open” to eliminate bathtub stopper swirling effect

- If a rotary valve is used, select valve with splined shaft-to-stem connection, integral cast of stem with ball or disk, and minimal seal friction to minimize backlash and stiction

- Use Teflon and for higher temperature ranges use Ultra Low Friction (ULF) packing

- Compute the installed valve flow characteristic for worst-case operating conditions

- Size actuator to deliver more than 150% of the maximum torque or thrust required

- Select actuator and positioner with threshold sensitivities of 0.1% or better

- Ensure total valve assembly dead band is less than 0.4% over the entire throttle range

- Ensure total valve assembly resolution is better than 0.2% over the entire throttle range

- Choose inherent flow characteristic and valve-to-system pressure drop ratio that does not cause the product of valve and process gain divided by process time constant to change more than 4:1 over entire process operating point range and flow range

- Tune positioner aggressively for application without integral action with readback that indicates actual plug, disk or ball travel instead of just actuator shaft movement

- Use volume boosters on positioner output with booster bypass valve opened enough to assure stability to reduce valve 86% response time for large signal changes

- Use small (0.2%) as well as large step changes (20%) to test valve 86% response time

- Use ISA standard and technical report relaxing expectations on travel gain and 86% response time for small and large signal changes, respectively

- Counterintuitively increase PID gain to reduce oscillation period and/or amplitude from backlash, stiction and from poor actuator or positioner sensitivity

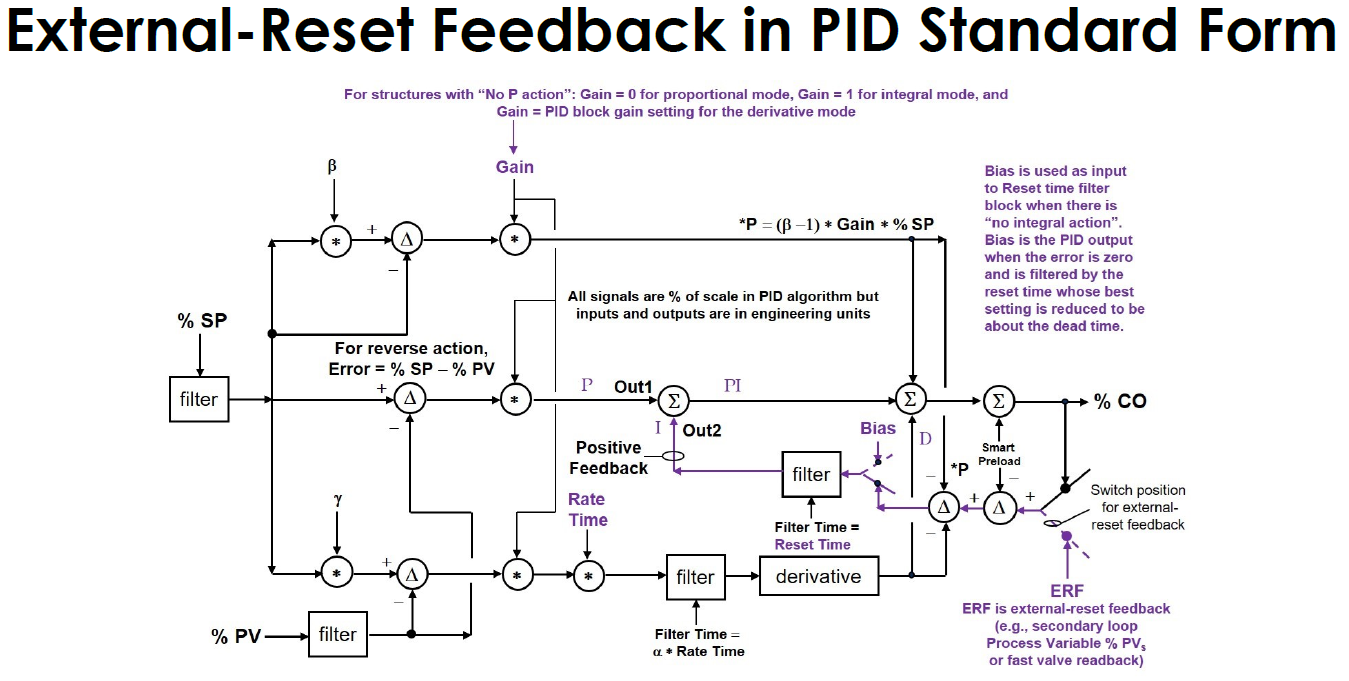

- Use external reset feedback of accurate and fast valve position readback to stop oscillations from poor valve precision and slow response time

- Use input and output chokes and isolation transformers to prevent EMI from inverter

- Use PWM [pulse width modulation] to reduce torque pulsation (cogging) at low speeds

- Use inverter duty motor with class F insulation and 1.15 service factor and totally enclosed fan-cooled (TEFC) motor with a constant speed fan or booster fan or totally enclosed water-cooled (TEWC) motor for high temperatures to prevent overheating

- Use a NEMA Design B instead of Design A motor to prevent a steep torque curve

- Use bearing insulation or path to ground to reduce bearing damage from Electronic Discharge Machining (EDM) that is worse for the 6-step voltage older drive technology

- Size pump to prevent operation on the flat part of the pump curve

- Use a recycle valve to keep the pump discharge pressure well above static head at low flow and a low-speed limit to prevent reverse flow for highest destination pressure

- Use at least 12-bit signal input cards to improve the resolution limit to 0.05% or better27. Use drive and motor with a generous amount of torque for the application so that speed rate-of-change limits in the VFD setup do not prevent changes in speed being fast enough to compensate for the fastest possible disturbance

- Use drive and motor with a generous amount of torque for the application so that speed rate-of-change limits in the VFD setup do not prevent changes in speed being fast enough to compensate for the fastest possible disturbance

- Minimize dead band introduced into the drive setup, causing delay and limit cycling

- For tachometer control, use magnetic or optical pickup with enough pulses per shaft revolution to meet the speed resolution requirement

- For tachometer control, keep speed control in the VFD to prevent cascade rule violation where the secondary speed loop is not 5 times faster than the primary process loop

- To increase rangeability to 80:1, use fast cascade control of speed to torque in the VFD to provide closed loop slip control as detailed in Resource 9

- Use external reset feedback of accurate and fast speed readback to stop oscillations from poor VFD resolution and excessive dead band and rate limiting

- Use foil braided shield and armored cable for VFD output spaced at least one foot from signal wires with never any crossing of signal wires, ideally via separate cable trays

You can find a lot more of Greg’s wisdom to help grow your process control & automation expertise in Amazon and with other booksellers.