Anyone who’s gone through the challenge of upgrading an operating system on a PC, smart phone, or other electronics device knows the complexities that can be involved. When looking at upgrading a process automation system in an operating plant, the difficulty of the task only increases.

There are many driving factors in seeking a control system upgrade including new functionality for increased performance of the process, reduced availability/increased shutdown risk of the aging system, obsolete parts, higher maintenance costs, cyber security-related risks, and loss of expertise using and maintaining the system—to name a few.

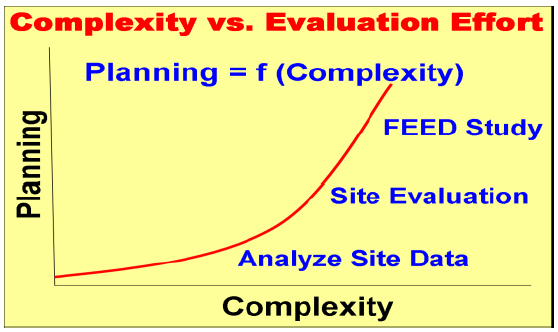

I caught up with Emerson’s Stephan Kerrebijn, a Senior Consultant on the Lifecycle Care Services team. Stephan highlights some considerations including so many integration pathways, such as OPC and SQL, which makes it difficult to upgrade the system. Upgrading a suite of complex online process controls software requires precise execution. The greater the complexity, the more effort must be put into upfront evaluation and planning. The Lifecycle Care Services team has an Evergreen Upgrade Program help work on process manufacturers upgrade projects in a structured way.

I caught up with Emerson’s Stephan Kerrebijn, a Senior Consultant on the Lifecycle Care Services team. Stephan highlights some considerations including so many integration pathways, such as OPC and SQL, which makes it difficult to upgrade the system. Upgrading a suite of complex online process controls software requires precise execution. The greater the complexity, the more effort must be put into upfront evaluation and planning. The Lifecycle Care Services team has an Evergreen Upgrade Program help work on process manufacturers upgrade projects in a structured way.

The planning process involves the process manufacturer’s organization and Emerson SureService engineers forming a team to assess the business needs and supplier recommendations. In general, they should:

- Set up the team to produce the plan.

- Determine the scope of the plan.

- Complete an inventory of all applicable equipment – hardware and software.

- Decide upon the required lifecycle strategy per identified device.

- Detail the lifecycle activity-based approach to maintain the system, maintain the functionality, optimize the system, change the functionality, and support the users. The ITIL (Information Technology Infrastructure Library) method can be used.

- Detail resource (Process Manufacturer, Emerson or other) and elapsed-time requirements, (Time – Scheduled, Call-Out, elapsed-time base, and frequency).

- Set methods for analysis and improvement – performance indicators.

- Implement the plan for all parties.

Stephan stresses that through advanced planning and working through the hardware and firmware vintages, various points of integration with other devices and software packages, and other non-standard parts of the system, issues can be identified in advance which leads to better decisions, reduced time to perform the upgrade, and planned timelines to incorporate the new system functionality.