Emerson’s Wendell Love, Alexandre Minto, and Joe Ugarte described applications on floating production storage and offloading vessels (FPSOs), floating liquefied natural gas vessels, and offshore oil and gas production platforms. Their abstract:

Demonstrate pressure solutions in firewater, HPU’s, Chem. Injection, Separator, Water control and Compressor Skids for instrumentation:

- High Pressure & subsea control solutions that optimize fixed investments and flow assurance.

- Minimize size & weight of current installation with self contained pressure control regulators.

- Minimize maintenance requiring less human interaction and calibration during commissioning.

- Improve overall production management with highly accurate pressure control, application experience & engineering support ensuring efficient and trouble-free operations

Joe opened describing how pressure control is used anywhere clean air, nitrogen, gas, steam, or water is used. Alexandre described a firewater distribution system. The end user was having issues in meeting emergency/safety operations requirements. During the Hazop studies, if a fire occurs in the Emergency Power Supply Room, the supply pressure from air would not actuate valves – valves in fail close position cause full firewater emergency system shutdown.

The solution was a self –contained (no power source) operated high capacity valve in parallel which were redesigned system using self-contained back pressure regulators. They used zero power draw so no additional cabling, trays and wires were needed. In a power failure the regulators would still control firewater system. In low pressure situations, regulators could maintain system backpressure for emergency use. Also, the project team reduced overall installation window by 0.9 m2 and weight of cable trays and wires by 20kg.

Wendell shared a story downtime & maintenance costs for hydraulic power units. The subsea oil & gas production installation experienced frequent regulator failures, complex startup procedures, and hours to fill umbilical through the regulator. The solution was high pressure regulators with automated integral fill valves. These regulators reduces high pressure components and potential leak paths. They are designed for the generalist, reducing complexity of operator fill procedures.

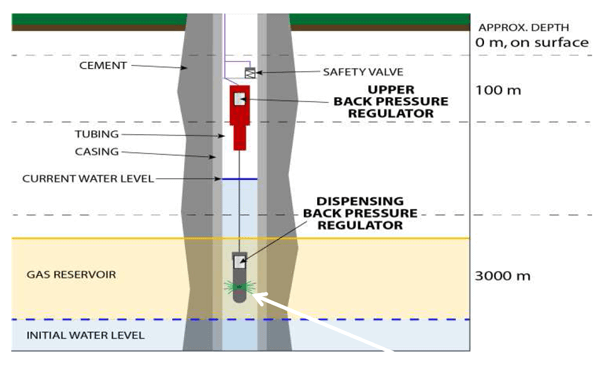

Another story shared was a need by an oil & gas producer for an artificial lift foam Injection system to have a cost effective method to relieve liquid loaded wells while maintaining safety regulations. The solution was to eliminate the need to modify the wellhead by generating downhole pressure controls. It includes an upper regulator for safety valve logic and a lower regulator that injects foamer for deliquification. This application can be installed into existing completions and helps keep mature wells profitable for a longer time period.

To connect and interact with other pressure regulator specialists, join the Regulators track of the Emerson Exchange 365 community.