Let’s continue the Temperature Insights video series with a closer look at diagnostics from these measurement devices. This 4-minute YouTube video, Temperature Insights – Benefits of Diagnostics Brief Video highlights the diagnostics that monitor the sensor measurement signal for a variety of conditions, identify troubled installations or damaged sensors, and provides the information to help keep a complex process operating at peak efficiency.

As processes become more complex, process upsets can occur that are more difficult to troubleshoot and resolve. It is important to identify issues before they become problems. For temperature measurement devices, diagnostics are available the monitor the RTD or thermocouple sensor signal for conditions such as drift, degradation, measurement validity, and broken or damaged wiring leads.

The temperature transmitter sends alerts or alarms to the operator to warn of a problem with the sensor or its environment. These diagnostics can help plant personnel avoid poor measurement reliability, measurement failures, or suboptimal process control—since the control loops rely upon the accuracy and repeatability of these temperature measurements.

Process disruptions occur as a result of poor measurement reliability. One example is electromagnetic fields which can disrupt the signal from the temperature measurement device back to the control system. The Rosemount EMF compensation monitors RTD sensor loops and filters out small voltages, allowing the transmitter to provide sensor measurements that are unaffected by thermal EMFs, resulting in a more reliable temperature measurement.

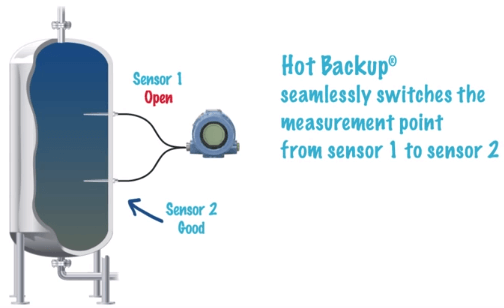

The most common measurement failures involve temperature sensors, given the harsh environments in which they often operate. A transmitter can be wired to two separate sensors or one dual-element sensor. With Hot Backup, should the primary sensor fail, the transmitter will automatically and seamlessly switch to the secondary sensor.

The most common measurement failures involve temperature sensors, given the harsh environments in which they often operate. A transmitter can be wired to two separate sensors or one dual-element sensor. With Hot Backup, should the primary sensor fail, the transmitter will automatically and seamlessly switch to the secondary sensor.

Optimal process control occurs within a range of operation. If the process variable from the temperature transmitter is still between the high and low alarm limits, measurement validation diagnostics can detect if the sensor reading is deviating from what it should be reading. By evaluating sample to sample temperature deviations over an historical trend, measurement validation can detect abnormalities in measurements related to degraded conditions such as: failing thermocouples or RTDs, electronic interference, excessive vibration, corroded termination points, loose electrical connections, or unexpected process variation.

Optimal process control occurs within a range of operation. If the process variable from the temperature transmitter is still between the high and low alarm limits, measurement validation diagnostics can detect if the sensor reading is deviating from what it should be reading. By evaluating sample to sample temperature deviations over an historical trend, measurement validation can detect abnormalities in measurements related to degraded conditions such as: failing thermocouples or RTDs, electronic interference, excessive vibration, corroded termination points, loose electrical connections, or unexpected process variation.

You can learn more about these diagnostics in section 3.1.8 of The Engineer’s Guide to Industrial Temperature Measurement. If you don’t already have your complimentary copy, order one today.

You can also connect and interact with other temperature measurement experts in the Temperature track of the Emerson Exchange 365 community.