Let’s continue our series of educational temperature measurement videos with a look at sensor wires. In this 3:32 YouTube video, Avoiding Long Sensor Lines, Emerson’s team managing the Rosemount Temperature products and services illustrates the relationship between sensor wire length and measurement accuracy. The video also highlights some factors to consider when deciding to use a transmitter or wire direct as well as the primary connection options for sending temperature measurement to the process automation system.

Historical practice has been to directly connect the temperature sensor wires to the control system’s or marshalling panel terminal strips. This “wired-direct” method leads to higher wiring and associated infrastructure costs, is more prone to electrical magnetic interference (EMI) causing reduced accuracy, is more costly to maintain, and limits the information coming from the sensor compared with other approaches such as transmitters.

Another approach is to connect the RTD and thermocouple sensor wires to remote I/O or multiplexer terminal strips. This approach can reduce the sensor wire length but are still limited from supplying advanced diagnostics which can aid in predictive maintenance and troubleshooting activities.

The commonly accepted best practice is to use transmitters which provide high noise immunity, improved accuracy, and broad diagnostics. The video shows a comparison of signals coming from a wired-direct sensor and a transmitter with large rotating machinery producing EMI. The signal from the transmitter is much cleaner and constant. The control system has a more accurate on which to make control, display and alarm actions.

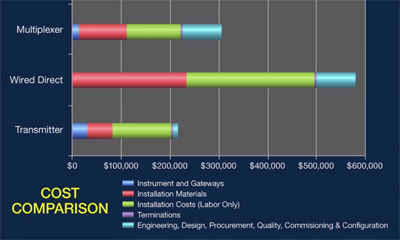

Cost of ownership is another factor in favor of temperature transmitters when considering the instrumentation, installation materials, labor, and required engineering to take the measurement from initial plan through commissioning.

Cost of ownership is another factor in favor of temperature transmitters when considering the instrumentation, installation materials, labor, and required engineering to take the measurement from initial plan through commissioning.

Locate the temperature sensor as close the transmitter as possible to improve overall accuracy, reliability, diagnostic coverage, and noise immunity.

You can find more guidance on which this series of videos is based in The Engineer’s Guide to Industrial Temperature Measurement. See section 4.3 on connecting to the control system. If you don’t already have the guide, order your complimentary copy.

You can find more guidance on which this series of videos is based in The Engineer’s Guide to Industrial Temperature Measurement. See section 4.3 on connecting to the control system. If you don’t already have the guide, order your complimentary copy.

You can also connect and interact with other temperature measurement experts in the Temperature track of the Emerson Exchange 365 community.