Increasing shale oil and gas production in the U.S. is increasing the need for storage tanks to hold it. One example as highlighted in a recent Bloomberg article, Houston Fills With Crude Oil That Can’t Be Shipped Out:

Storage tanks are filling as new pipelines carry light, sweet oil found in shale formations to the coast and U.S. law keeps companies from moving it out. Most crude exports are banned and the 13 ships that can legally move oil between U.S. ports are booked solid.

Chris Amstutz

Director Terminals, Tanks and Transportation

For many terminal operators, current instrumentation does not provide the required insights into current tank inventories. Wiring these measurement devices back to the control rooms is technically and economically difficult given the distances involved. As a result of limited measurements, operators at the facilities cannot see the process operations occurring within and between tanks. Also, the lack of measurement devices can make it insufficient to detect potential safety and environmental incidents early enough to avoid losses. These losses can potentially be in the millions of dollars.

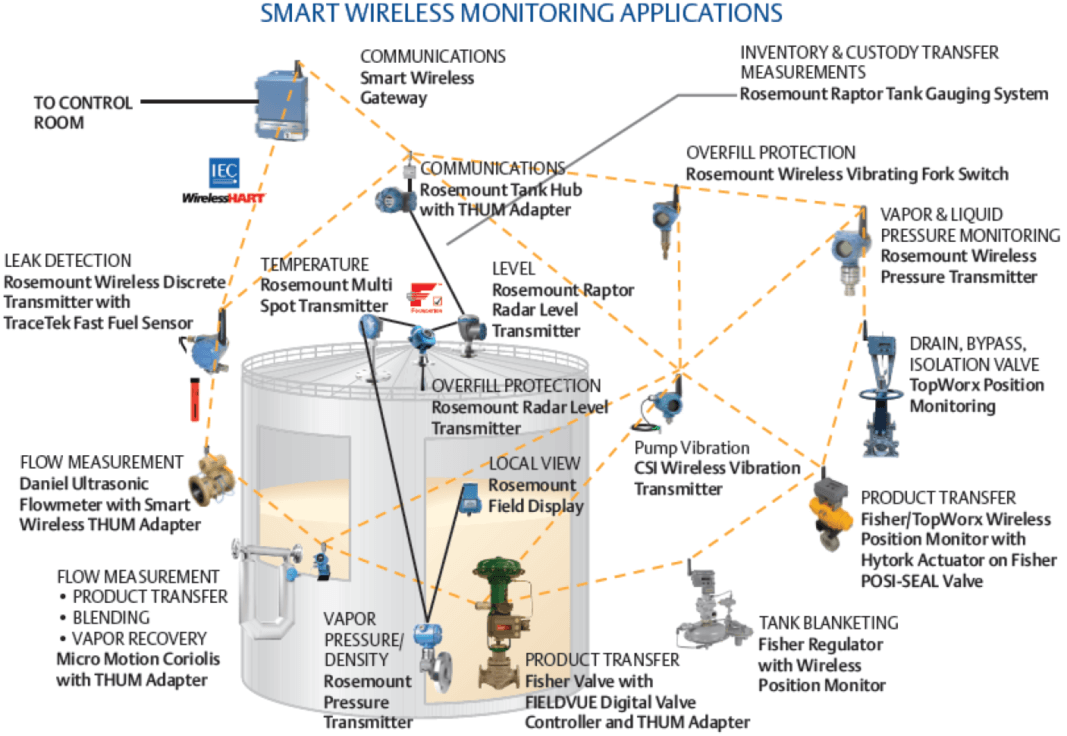

To address some of these blind spots in the process operations, wireless technology has come to process instrumentation. IEC 62591 WirelessHART instrumentation has logged billions of hours of operations in process operations. There are hundreds of thousands of smart wireless devices installed on tens of thousands of networks. The networks are self-organizing, self-healing, and operate across many changes for secure, robust, and reliable communications.

Some of the factors that has driven the growing use of wireless instrumentation in the process industries is the need for greater visibility into the process, the need for stricter safety standards, such as API 2350 overfill protection for storage tanks, retiring expertise, and shrinking profit margins for terminal operators.

Chris notes that wireless devices can replace control system I/O, marshalling cabinets, and the field distribution cabling and associated cabling infrastructure. Activities such as installation, commissioning, engineering, and materials can be reduced 70% compared with traditional wired instrumentation projects.

Around storage tanks, Chris shares these many applications for wireless technology using Emerson products:

He notes how a wrong valve position caused a fuel leakage which lead to a fire and explosion which resulted in all 11 storage tanks being destroyed in a 2009 terminal fire incident. Wireless valve position monitors are one way to check for correct valve positions.

Other applications for wireless instrumentation include overfill monitoring on truck loading operations, pump run dry protection, tank overfill protection, hydrocarbon leak detection, floating roof monitoring, loading arm pressure monitoring, and tank blanket pressure monitoring. He shares several examples where these applications were placed into operation.

Chris closes his presentation noting that wireless technology can challenge the status quo of limited insight into terminal operations. It’s been proven over many years, lowers project costs, easily expands over time, and variety of applications is limited only by one’s imagination.

You can connect and interact with Chris and other terminal experts in the Tank Gauging and Oil & Gas tracks in the Emerson Exchange 365 community.

Update: Here’s Chris in action presenting at the conference.