A customer was having issues with maintaining control over their waterflood system due to valve failures. This application, key to optimal oil/gas production and maintaining reservoir pressure subjects the valves to an eight to as high as ten thousand psi pressure drop. The valves Fisher replaced clogged and began to cavitate until they were damaged beyond use. The system was down without them. The waterflood system greatly enhances production. When this system is not running production declines by as much as 3K barrels per day. At today’s oil prices, that is a potential loss of approx. $150K per day!

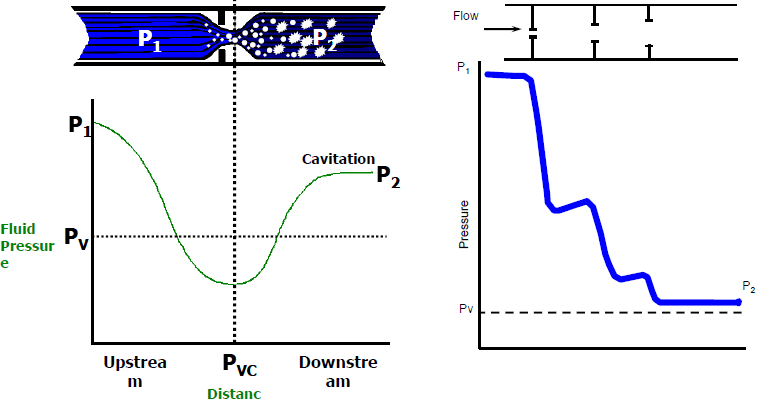

Ryan opened describing the challenge of the oil and gas producer needing to Increase availability of the waterflood system found on an offshore oil platform in the Gulf of Mexico. This low availability had financial impact and a fast solution was needed. High pressure drops were a technical challenge in finding the right solution. These high-pressure drops caused valve failures and pipe damage due to cavitation.

Ryan described the waterflood process a secondary recovery technique in which water is injected into the reservoir through injection wells causing the oil in the reservoir to be pushed towards the production wells.

To solve these issues they first had to analyze the existing conditions on the injection wells.

Ryan described the engineered solution required for the valve to meet these process conditions:

- Process conditions are received and the valve is sized.

- Emerson’s special product engineer evaluates the process conditions and Emerson’s sizing tool output to begin to engineer a valve for the customer’s given process conditions.

- Materials of construction are discussed and accepted by the end user.

- End connections are verified to match customer’s piping requirements

- The valve is designed per ASME B16.34 to meet or exceed pressure and temperature requirements for an API 10000 construction.

The solution was a Fisher CAV4 Control Valve Design with a protected seat, staged pressure drops utilized to prevent cavitation, high strength/corrosion resistant materials and integral RTJ end connections. The valve included a Cavitrol IV Trim Design which includes protected seating, surface, multi-stage pressure drop, unequal pressure drop staging, shrink fit cage sleeve, axial flow path, adequate recovery volumes, and customizable.

The customized solution was developed and shipped in 20 weeks. The results achieved included:

- Reduction in safety concerns due to past valve failures.

- Reduction in maintenance time and costs associated with replacing the previous poorly performing valves.

- Increased production due to the reduction of downtime, upwards of 3000 barrels of oil per day.

- Financial impact of the increased production resulted in approximately $150,000 per day.

For more information visit the Fisher oil & gas page.