Whether it is students preparing for a test or seasoned engineers planning an automation project, early planning and preparation improves the odds of success.

Congratulations to Emerson’s Laurie Ben for receiving an Outstanding Presentation Award from the AIChE Fuels and Petrochemicals Division for her AIChE Spring Meeting presentation, An Introduction to Early Planning Process for Plant Automation Projects.

Congratulations to Emerson’s Laurie Ben for receiving an Outstanding Presentation Award from the AIChE Fuels and Petrochemicals Division for her AIChE Spring Meeting presentation, An Introduction to Early Planning Process for Plant Automation Projects.

Laurie opened her presentation with the problem process manufacturers and producers face in prioritizing capital for the best return. Process automation projects face many obstacles:

- Inadequate resources for planning investments

- Corporate hurdle rates

- Obsolescence will not justify replacement

- Scarce expertise in process control

- Engineers focused on day-to-day operations

Early project planning has many considerations such as feasibility, order of magnitude cost estimations, conceptual engineering, pre-Front End Engineering Design (FEED), FEED and Front End Loading (FEL)—where does it begin and where does it end?

Laurie shared a simple example of kitchen remodel product to illustrate considerations in the project cycle. The cycle contains five steps:

- Need it?

- Doable? Options? Costs? Funds?

- Detail the plan and schedule

- Agree with supplier on specs

- Commission: own it, take care of it

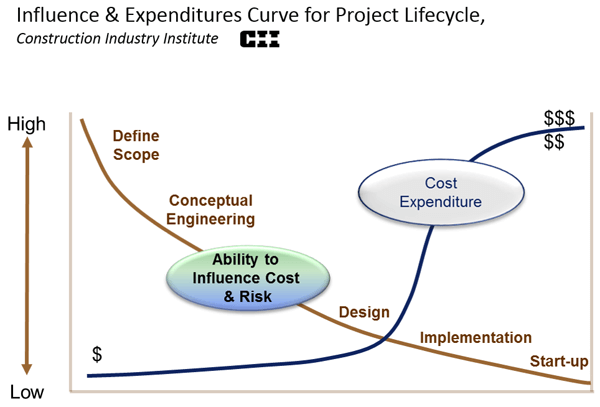

A process automation contains phases that line up with these steps: Appraise, Select, Define, Execute and Operate. Laurie shares research from the Construction Industry Institute (CII) show the benefit of early planning in terms of influence on the project and project costs. Costs significantly increase as changes are made late in the project and ability to influence cost and risk is greatest early in the project lifecycle.

The Independent Project Analysis (IPA) organization research data shows that project management best practices increases ROI by 7.5% for the best performing projects, decreases project duration by 30% and provides 6% additional capacity.

Laurie also shared CII’s Project Definition Rating Index (PDRI), which fosters discussions among the project team along a number of dimensions—products, capacities, technologies, processes, process flow sheets, site location, P&IDs, etc. The discussions and checklist evaluations based on current status are performed at stages across the project lifecycle. This methodology helps identify risk areas earlier in the project when mitigation is easier and less expensive to perform.

She walked through a stage-gate process through phases including conceptual design, preliminary design, detailed design, final design and commissioning, qualification and validation (CQV). After the preliminary design phase the scope of project is typically frozen. After detailed design, the capital for the project is approved, etc.

Each phase produces greater accuracy of project costs and benefits. In the first phase, Appraise, cost & benefits are typically estimated within 50%. The Select phase refines this estimate to the order of +/-30% and the Define phase to +/-10% where the final investment decision is typically made.

Laurie notes that it is important to understand your company’s capital budget methodology and gating process, as well as where you are at in the phases of this process. It is critical to know the drivers—key business and operational issues—for the project to develop justification to sell the project to get capital approved.

Following some of the well-researched methodologies from CII and IPA helps to establish best practices and early project planning which greatly improves the odds of a successful project.

Laurie will be co-presenting Getting Your Modernization Project Approved at the October 12-16 Emerson Exchange conference. It explores some of these ideas in depth and gives you a chance to ask question. Join us in Denver if you can!

You can also connect and interact with other project experts in the Plan & Design group in the Emerson Exchange 365 community.