We opened this week with a look at how the Industrial Internet of Things (IIoT) is changing the traditional view of information flow through the process manufacturing and production enterprise as defined by the Purdue Enterprise Reference Architecture developed in the 1990s.

Continuing on this theme is a presentation given last year at the Regional IoT Forum in Singapore by Emerson’s Jonas Berge. The one-hour presentation, Plant Modernization with Pervasive Sensing opens with Jonas describing how additional sensors have improved everything from Formula 1 racing cars to the modern cars that we all drive compared to earlier generations of cars.With these additional sensors, today’s cars are more reliable, fuel efficient, environmentally friendly and safer than their predecessors. And, many of these sensors are wireless given how difficult or impossible running wires would be.

I’ll highlight several points from Jonas’ presentation and invite you to view the rest. For cars, Jonas described two systems—one for the driver with simple indicators and another for the mechanic with detailed diagnostics. Similarly, with IIoT sensors—information can be directed with the appropriate level of detail required to rapidly solve the issue at hand.

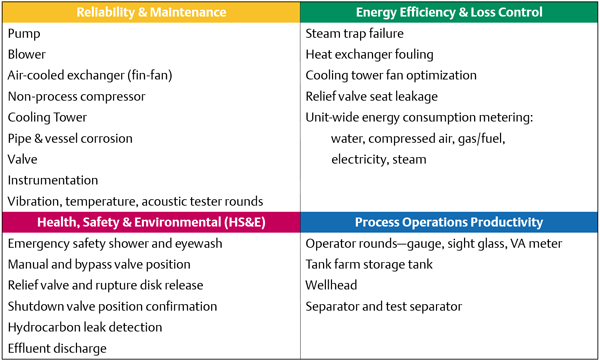

Jonas explains four key areas where additional measurements can improve plant performance. These include reliability & maintenance, energy efficiency & loss, health, safety and environmental (HSE) and process operations productivity. These are the applications beyond the control room where missing measurements are likely and wireless sensors can easily be added. Communication technologies such as WirelessHART are self-organizing, multi-path and multi-hop to deliver the measurements where they need to go. Jonas refers to this capability for these additional measurements as pervasive sensing.

Even the installation methods have changed with methods to clamp-on, strap-on, bolt-on, stick-on, affix via magnet and slip in avoid the need to cut, drill and/or weld into pipes and other vessels.

The list of possible applications in these four key areas is large and growing:

Watch the video for more on how pervasive sensing as part of an IIoT architecture helps to improve operations in each of these areas.

You can also connect and interact with other measurement experts in the Wireless group in the Emerson Exchange 365 community.