One of the most transformational cost-reduction trends in the automation industry is the application of configurable I/O.

Based upon the projects standards premise, reduced installation and commissioning time – along with the inclusion of late stage project changes without cost – configurable I/O is a technology that is critical to the optimization of project execution strategies.

However, not all configurable I/O offerings are equal. These technologies must support all types of I/O and wiring options. This includes built-in field termination assemblies, which eliminate traditional marshaling and provide for I/O that can be assigned to a number of controllers at any time during the design, installation, commissioning, or operational phase of a project.

However, not all configurable I/O offerings are equal. These technologies must support all types of I/O and wiring options. This includes built-in field termination assemblies, which eliminate traditional marshaling and provide for I/O that can be assigned to a number of controllers at any time during the design, installation, commissioning, or operational phase of a project.

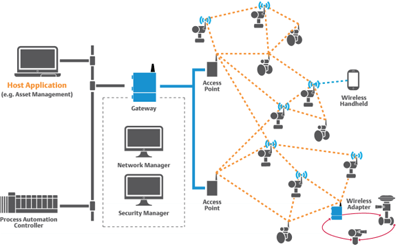

In addition, implementing wireless technologies not only eliminates costs associated with engineering and installation, but also allows people to perform their job from anywhere. This will challenge us to overcome the traditional culture; driving the need for “smart applications” to provide field operations teams with the status of all assets and immediate access to all forms of intelligent technologies on phones, PDAs, and other mobile devices. This will ultimately allow field personnel to predict changes – in demand or operation – prior to the event occurring at the gas processing facility, avoiding process downtime and changes in product quality.

We also see that the Internet is now available everywhere and has the potential to be a big tool for the gas processing industry. Big data and analytics will facilitate a deeper understanding of the process and allow all personnel to be more aware of what’s going on. It will also give them the ability to collaborate with other departments and stakeholders and operate in a more cost efficient and sustainable manner.

A whole new generation of low-cost and easily maintained wireless sensor technologies will be the fundamental contributor to the development of big data, eliminating the need for wiring and installation. It’ll be innovative and transform the process industry in the same way that similar sensing technology changed the medical, avionics, and financial industries.

A whole new generation of low-cost and easily maintained wireless sensor technologies will be the fundamental contributor to the development of big data, eliminating the need for wiring and installation. It’ll be innovative and transform the process industry in the same way that similar sensing technology changed the medical, avionics, and financial industries.

An example might be in a fire and gas system where a single infrared device continuously covers a wide area with embedded analytics, which can be supplied with the intelligence to make decisions about alarming and other control actions.

Other applications like detecting hazardous emissions, corrosion, asset reliability, and energy management will require not only the sensors, but a whole new set of innovative application packages that are easier to maintain at a lower overall cost.

From Jim: You can connect and interact with other midstream oil & gas experts in the Oil & Gas group of the Emerson Exchange 365 community.