The Schlumberger Oil Field Glossary defines a stock tanks:

A storage tank for oil production after the oil has been treated.

As oil is held in these stock tanks, residual natural gas and other vapors can flash off and collect above the liquid level. Vapor recovery is the process to collect, compress and prepare this gas to be used or sold and send the liquid condensates back to the liquids in the tank.

In a Compressor Tech article (archived), Harvesting Profits From Emissions, Emerson’s Lou Heavner and Thomas Hoopes describe how smart vapor recovery helps to reduce emissions and increase sales of these natural gas and hydrocarbon components.

They open noting the regulatory environment in the United States with the Environmental Protection Agency’s (EPA’s) 40 CFR 60, Subpart OOOO (Quad O) regulations. The purpose of these regulations is:

They open noting the regulatory environment in the United States with the Environmental Protection Agency’s (EPA’s) 40 CFR 60, Subpart OOOO (Quad O) regulations. The purpose of these regulations is:

…for controlling volatile organic compounds (VOC) and hydrocarbon emissions from sources such as compressors, storage vessels, pneumatic controllers, equipment leaks, etc., commonly found at oil and gas sites. For example, a storage tank that emits 6 tpy (5.4 T/yr) of VOCs or greater must now be equipped with a control device to reduce the VOC emissions by at least 95%.

Further regulations from the EPA for methane emissions have the goal to:

…curb methane emissions by as much as 45 percent from 2012 levels by 2025.

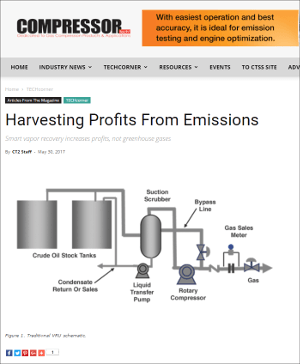

They explain that these VOCs may be handled with vapor combustion units, flares, incinerators or vapor recovery units (VRUs). Traditional VRUs:

…are designed to recover up to 95% of VOC emissions from sources such as storage tanks, compressors, product loading/unloading racks and others.

The compounds in the recovered VOCs can approach twice the BTU content of natural gas alone so these have value to capture and sell to add incremental revenues to the production facility.

Operating and maintaining traditional VRUs can pose challenges. For example:

…contamination of the lube oil used in a compressor by presence of wet gas is a critical issue since operating a compressor with contaminated lube oil may result in loss of oil viscosity and cause catastrophic failure of the compressor.

Unlike traditional VRUs, a Smart Vapor Management (SVM) solution:

…is designed to incorporate advanced temperature and pressure control strategies to eliminate hydrocarbon dilution of the compressor oil system.

They explain the operation of an SVM. It:

…draws vapor from one or more storage tanks, and includes a suction scrubber, a scroll compressor to boost the pressure of recovered gas to match pipeline distribution requirements, a bypass valve designed to divert a portion of the discharge stream back to the suction scrubber, a heated multistage gas/oil stabilizer, and an oil cooler.

The scroll compressor can run at variable speeds from 0 to 100% duty cycles to maintain pressure and avoid the on-off cycles of traditional compressors. From an operating and maintenance perspective, a scroll compressor:

…has zero leaks or emissions due to its hermetically sealed design that eliminates need for shaft seals, drive belts, drive couplings, lube points or a system oil pump.

Visit the Smart Vapor Management and Vapor Recovery Solutions sections on Emerson.com to learn more about these tank blanketing and vapor recovery solutions.

You can connect and interact with other oil & gas experts in the Oil & Gas group in the Emerson Exchange 365 community.