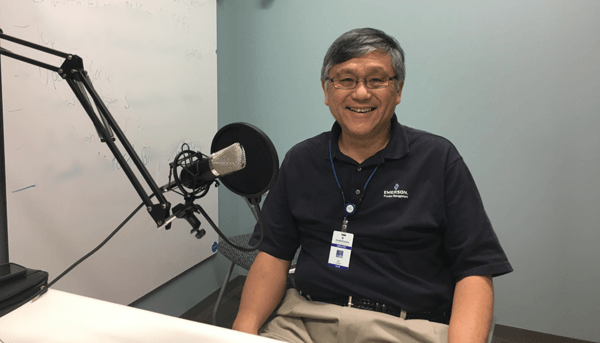

Let’s continue our 5 Questions for an Emerson Expert podcast series with MC Chow. MC has more than two decades of experience in process automation and safety. He works with process manufacturers and producers to modernize their control and safety systems in order to improve safety, reliability and efficiency.

If you have an Emerson expert you’d like me to interview and questions to ask, leave me a comment below… thanks!

Transcript

Jim: Hi, I’m Jim Cahill. And today, on the “5 Questions for an Emerson Expert” podcast series, I’m joined by MC Chow. MC is a control and safety system modernization consultant who helps process manufacturers, create a vision, and identify opportunities to improve safety, reliability, and efficiency when planning to modernize their control systems. He has more than 20 years’ experience in process automation and safety. Welcome, MC.

MC: Thank you, Jim.

Jim: So I always like to start out and ask, when you were growing up, what led you to study in one of the fields of science, technology, engineering, and math, specifically mechanical engineering and then control engineering in your case?

MC: Yeah. Good question, Jim. When I was growing up, I was a bit of a car nut. I enjoyed looking at pictures of cars. And my uncle was a mechanic, and he let me work on his cars. We worked on some of things that…and he taught me a lot about working on cars. So I was mechanically inclined growing up. When I got into high school, one of the things I really wanted to do was become an automotive engineer. But when I found out how little opportunities there were where I was growing up, I took a class in mechanical engineering and then ended up enjoying it. And that actually leads me into the next part, where my first job was actually going back with a fisher rep in Malaysia, where I grew up, and that introduced me to the world of process automation and control. Doing that for three years, I thought I needed more education. So I went back to school and got my bachelor’s degree in control engineering.

Jim: Well, that’s a fascinating path into our industry, and I guess that also describes that path. So that was your starting point into process safety and automation, or where did the safety part come in?

MC: Well, if I back up, before I got into safety, when I got that first job with the Fisher Rep, I had no idea what a control valve was. That introduced me to the world of process automation and control. So going through that, after my bachelor’s degree, I went fully into the world of instrumentation and control. And the safety part kicked in a little bit later, maybe five years into my career. I learned about process safety and what a safety system was, and that peaked my interest, and I ended up self-teaching myself a lot of the safety aspects of our industry. And as it evolved into the process safety management regime that we have today, that set me up very nicely in the early years. Somehow, it just caught on with me, and I developed a personal interest in it, and it grew. And, thankfully, working with Emerson, I got into the Emerson world with a local business partner in the early days of the Emerson DeltaV SIS product, and that was the springboard to my deeper dive, if you like, into the process safety world.

Jim: That’s great. So tell us about a recent consulting engagement that you’ve been involved with.

MC: I thought long and hard about this. All the consulting engagements that I have been involved in two years into my current role has been interesting, but the one that I thought of most had elements of both the process control and safety. I visited a refinery in the northern part of the U.S., small one, which I was asked to come in and consult with a customer about migrating their Legacy Emerson process control system, as well as look into a number of safety systems that they had implemented, which they thought was suboptimal, and they wanted to find a better way of doing that. So that combined the two elements of my passion, with process control modernization as well as safety systems, and that took a little while to develop.

A lot of my role is early engagement, so we typically don’t see the results till much later in the process. And this was almost two years ago. It’s one of my earlier engagements when I was with Emerson. And recently I heard that this customer had decided to go upgrade and update their process safety systems with DeltaV SIS and making plans to upgrade their older legacy Emerson process control system to DeltaV. So I’ve had the opportunity to see the fruits of that consulting engagement, so that’s why I thought long and hard about that and then combined the two elements of what I have passion in.

Jim: Yeah. That’s one thing about this industry, sometimes that work you do takes years to bear and see the results of it.

MC: That’s true, yeah.

Jim: So that’s great. So as fun and exciting as process automation and safety is, outside of all this, what do you enjoy doing in your spare time?

MC: Spending time with the family. We have a small family, and my daughter’s almost finishing college. And my wife and I, even though we’re empty nesters, there’s lot to do at home, so I enjoy doing that, spending time on the work at home with my wife. And we do workouts on the cheap, we walk. We walk the neighborhood. And that’s what I enjoy most.

Jim: I will tell you I’m very similar in that regard. And I guess, as a final wrap-up-type question, for those new and coming into the industry, what advice would you have to give them to accelerate their learning curve?

MC: First of all, if you’re listening to this podcast and you relate to the topics we’re discussing, automation, control, process safety, you’re well on your way. As I mentioned earlier, I stumbled into the industry without knowing what it was. And now that you’re listening to this, it is helpful that you are aware that there is this industry out there. It has developed a lot over the years.

And I would say get a mentor. A lot of vendors have training programs. If you’re fortunate enough with your employer that they will pay for your training program, get trained, learn the fundamentals. I don’t believe they teach that well enough in school, at least when I went to school. And even though I went to school in control engineering, a lot of the practicalities and the realities of real-life process control engineering isn’t apparent when you’re in school. So get the practical training.

Get involved in a professional organization like the ISA. Get involved. And with STEM programs that are process control and safety orientated, learn as much. And there are a lot of resources on the web today, free webcast, free podcast, you’re listening to this. My employer, Emerson, has lots of resources that you can tap into at no charge, so go for it. It’s a much broader, deeper feel of knowledge than I had when we were starting up, so go for it. And this is a great time to be in process control instrumentation and process safety.

Jim: That’s some great advice. Thank you so much for joining us today.

MC: Thank you, Jim, appreciate it.

You can connection and interact with other control system migration and modernization experts in the Improve & Modernize group in the Emerson Exchange 365 community.