Refineries are not the first to jump on new technology trends given their need for stable and predictable operations for such a complex process. But as technology continues to advance, scalable ways to try, prove and grow solutions that create value are possible.

In a Hydrocarbon Processing article, An evolving approach to digitalization, Emerson’s Tonya Wyatt and Ron Fleissman share ways for refineries to incorporate Industrial Internet of Things technologies in a scalable way to prove the value they can deliver.

They open highlighting some common concerns, which:

…include the security of the data gathered and where it might be stored, along with the cost of retrofitting existing equipment and legacy systems, and the importance of the reliable functioning of software within critical business processes.

A key objective on the road to digitalization should be to eliminate silos.

Separate silos of information and manual-based processes that only track one set of data have few parts to play in the digital refinery of the future. Simultaneously, data collection and analysis need to be made easier, while there is also still ongoing pressure on refinery managers to get more done with fewer resources (financial and personnel).

Collecting data alone is not sufficient. It needs:

…to be presented in a format that provides actionable information that, in turn, needs to drive refinery decision-making and tangible operational improvements. For example, without quick and accurate data analysis, it can be difficult to prioritize maintenance and identify potential hazards or failures.

One place to start is to look for the existing digital sensors.

These may have traditional digital outputs such as HART that can provide more than one variable using traditional twisted pair wiring or using WirelessHART adapters to a gateway device. The digital outputs can feed data to software applications that can provide real-time analysis of key asset data without the major capital investments of new systems and technologies.

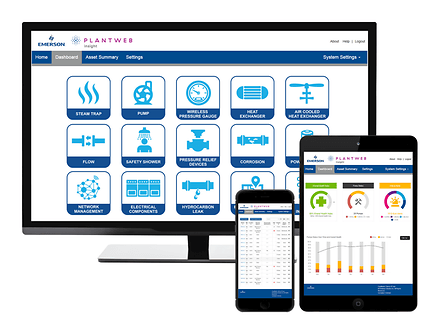

Operational analytics available on mobile platforms for this data can enable:

…a much more responsive and agile refinery, with the ability to access actionable data nearly immediately via a purpose-built app for each asset.

One example considering flowmeters is that:

…it is possible to quickly determine the health of each meter and identify which meters are not performing within set parameters. All information can then be displayed on a dashboard, allowing a quick assessment of asset health, with the ability to drill down to the device that has health issues.

Read the article for examples of creating quick wins in performance improvements around heat exchangers and steam traps, as well as ways to address security, safety and regulatory concerns.

Visit the Industrial IoT and Plantweb digital ecosystem sections on Emerson.com for more on the technologies and solutions available to help drive top quartile operational performance. You can also connect and interact with other digital transformation and refining industry experts in the IIoT & Digital Transformation and Refining groups in the Emerson Exchange 365 community.