At the Emerson Exchange Americas Virtual Series, Emerson’s Jennifer Andrews and Tony Foster shared how digital technologies are changing how engineering work is performed. Here is the abstract of their presentation and demonstration:

Digital tools are transforming the way engineers do work. Whether researching new solutions, specifying and procuring equipment, or collaborating with experts, engineers are under pressure to complete work quickly and accurately. MyEmerson delivers digital tools and collaborative workspaces to share information across teams as well as easily connecting to Emerson experts for additional insight. Enter process conditions to generate sizings, configurations, and technical drawings on demand. When engineering is finished, seamlessly move information from engineering through quoting and purchasing. Learn how digital engineering tools can enable teams to work and collaborate more effectively.

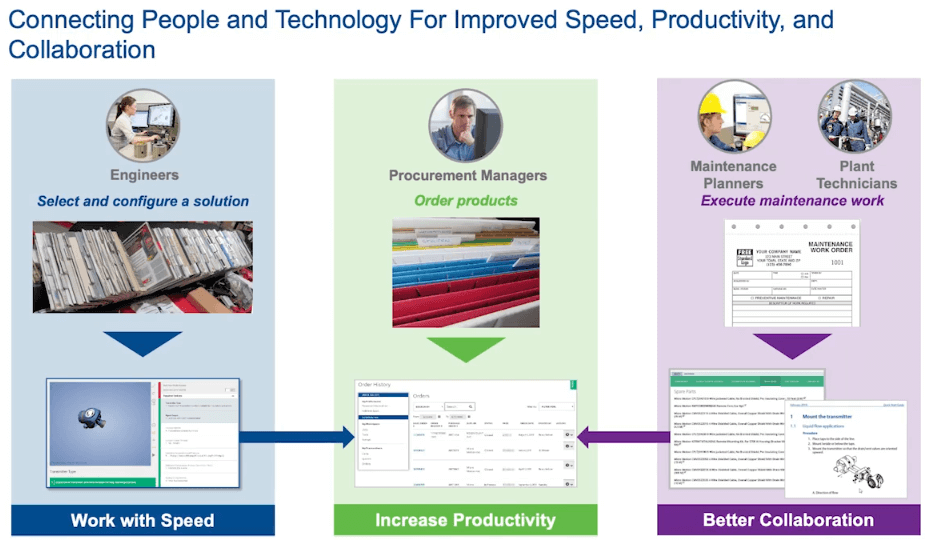

The goal of using these digital tools is to connect people and technologies for improved speed, productivity and collaboration in their day-to-day work.

Jennifer and Tony asked all the participants to follow along with the demo by signing in or registering for an account in MyEmerson.com. Jennifer then describes MyWorkspace, which is a collaborative digital engineering environment. This workspace is a multi-user shared environment with instant updating and automatic saving of work. It enables collaboration within your organization, with Impact Partners and Local Business Partners, and with Emerson.

The workspace organizes engineering work, with a single view of sizings and configurations, technical specifications, team notes and more. in the portfolio of engineering tools available in MyWorkspace include sizing and configuration tools, sizing reports, and CAD drawings to reduce these engineering efforts from days to minutes.

Jennifer shared an example of putting in process parameters such as flow rates, Reynolds number, pressure loss, etc. to identify the right measurement instrument for your application. She also showed how you can use a visual configurator to properly specify the instrument based on what’s required for the application. These include materials of construction, accessories, pipe fittings, and other parameters to properly specify the instrument.

There is a self-service area for product-specific drawings which enable you to have more accurate CAD models. You can access model numbers specific drawings as 2D PDF files and 3D CAD formats for many products. The library continues to be expanded with more product drawings over time.

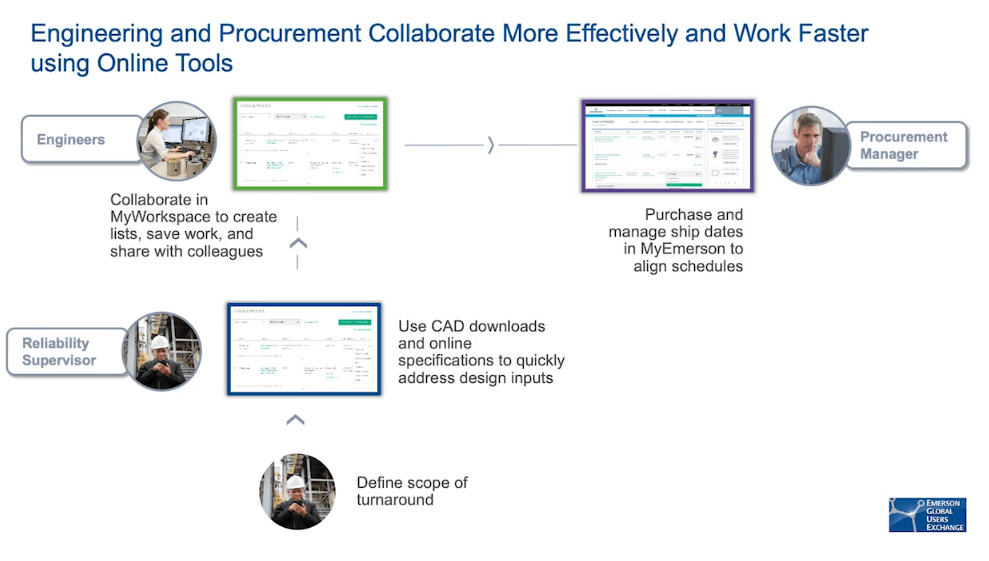

A sample workflow for turnarounds begins with defining the scope of the turnaround. The reliability supervisor uses CAD downloads and online specifications to quickly address design inputs. This is shared with the engineers collaborating in MyWorkspace to create lists, save work, and share with colleagues. Once the specifications are complete, the procurement manager can access that same information to purchase and manage ship dates in MyEmerson, ensuring alignment to project schedules.

Visit the MyEmerson Personalized Digital Experience section on Emerson.com for more ways to drive measurable productivity gains through streamlined processes and increased collaboration.