One of the reoccurring themes I heard at the recent Emerson Exchange conference for process manufacturers modernizing their control systems was the early engagement of operators in training systems. I met with Emerson’s Ronnie Bains a few months back who is involved in many operator training system (OTS) projects, as part of the Strategic Services Europe OTS team.

One of the reoccurring themes I heard at the recent Emerson Exchange conference for process manufacturers modernizing their control systems was the early engagement of operators in training systems. I met with Emerson’s Ronnie Bains a few months back who is involved in many operator training system (OTS) projects, as part of the Strategic Services Europe OTS team.

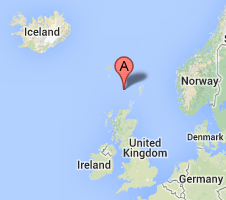

Ronnie shared with me that they have just been awarded a project to develop a high fidelity dynamic simulation for a major re-development of the deepwater Schiehallion and Loyal oil fields in the North Sea. The DeltaV OTS will be used to support the training of operations personnel, assist in commissioning and be core to achieve safer and more efficient operation of the asset.

Ronnie shared with me that they have just been awarded a project to develop a high fidelity dynamic simulation for a major re-development of the deepwater Schiehallion and Loyal oil fields in the North Sea. The DeltaV OTS will be used to support the training of operations personnel, assist in commissioning and be core to achieve safer and more efficient operation of the asset.

Ronnie noted that this project is the largest OTS done to date by his team or any team across the globe. A driving factor for the operator of these fields is that it enables them to train, commission and optimize the operations staff in a realistic non-intrusive environment, identical to the main project.

He shared with me that the dynamic simulation was an important part of bringing realism to the training. A major engineering contractor, based in Houston, Texas, is providing the high-fidelity process model. As I highlighted in an earlier post, Building Competency through Operator Training Systems, the project team will also use a standardized implementation approach, SEEDS (Standard Entities for the Engineering of Dynamic Simulators). It consists of a library of native DeltaV simulation objects to help implement the high fidelity process model in the DeltaV OTS simulation.

The simulation includes subsea simulation in addition to the topside process. The finished operator training system will be located in the operator’s learning center in their U.K. headquarter office after being used for training in Aberdeen.