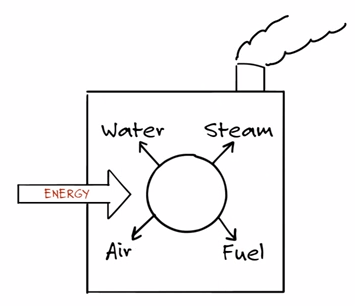

Process manufacturer’s operating budgets typically require 25-30% be spent on utilities—energy for steam, air, fuel, and water.

Process manufacturer’s operating budgets typically require 25-30% be spent on utilities—energy for steam, air, fuel, and water.

For energy intensive industries such as steel manufacturing and refining, these costs can be in the tens to a hundred million dollars per year.

Emerson’s Rosemount Measurement team has a new 2:51 video, Identify energy savings in your process plant — Rosemount Energy Management Solutions.

It highlights ways to reduce energy consumption.

The video shares the statistic that 20-25% of the steam and air required for its intended use is lost. Instituting a focus on energy management can reclaim some of these losses, helping to reduce operating expenses.

Measurement technologies such as steam trap monitoring can spot and report losses in real time.

The team has a website, Rosemount.com/energy, which includes a virtual tour to see how to better analyze energy use and to develop effective strategies to manage energy use.

To connect and interact with fellow energy management experts, join the Industrial Energy track of the Emerson Exchange 365 community.