Process manufacturers and producers are under constant pressure to improve performance to remain competitive and maintain ongoing profitability. Technology can help play a large role in increasing performance through reliability, production availability, energy and emissions reductions, improved safety and security, and overall production optimization.

Advancements in technologies and work processes not only come from manufacturers and suppliers, but also from consortiums that may also include academic researchers and governments. In an earlier post, Collaborative Initiative to Show Real-Time Energy Use Management, we highlighted the work of the Smart Manufacturing Leadership Coalition (SMLC), which supports the manufacturing industry by pursuing a comprehensive technology that no one company can undertake.

I caught up with Emerson’s Mike Boudreaux who recently attended the Clean Energy Smart Manufacturing Innovation Institute (CESMII) meeting in College Station, Texas. Texas A&M University is the home to the Gulf Coast Regional Manufacturing Center, one of five centers located across the United States. From the Texas A&M announcement:The Smart Manufacturing Leadership Coalition, headquartered in Los Angeles, California, will lead CESMII, in partnership with the Department of Energy.

CESMII is the ninth of 15 innovation institutes planned to be launched by the National Network for Manufacturing Innovation (NNMI). It brings over $140 million USD in public-private investment from leading universities and manufacturers. Again, from the Texas A&M announcement:

The coalition brings together a consortium of nearly 200 partners from across academia, industry and non-profits—hailing from more than 30 states—with a goal to spur advances in smart sensors and digital process controls that can radically improve the efficiency of advanced manufacturing in the United States.

The objective of CESMII is to develop a platform for data to solve problems. Smart Manufacturing is about data. How you obtain it, manage it, and use it—not about big data, but rather about smart data. The intent is to use an open-source digital platform and technology marketplace to integrate advanced sensors, controls, platforms, and modeling technologies into commercial smart manufacturing systems. The goal is to provide manufacturing communities with easy and affordable access to real-time analytic tools, infrastructure, and industrial applications.

The Gulf Coast Regional Manufacturing Center’s primary focus is innovations for the chemical and petrochemical industries. The U.S. Gulf Coast region is strongly represented by the oil & gas upstream, midstream, downstream and chemicals industries, primarily in Texas and Louisiana. Given the strong chemical industry presence also in West Virginia and Pennsylvania, companies and universities from these states are represented in the coalition as well.

Some of the members from the chemical and petrochemical industries include Dow, Shell, Halliburton, Baker Hughes, BASF, ExxonMobil, General Mills, and Praxair. Universities include Texas A&M, University of Texas in Austin, University of Houston, Tulane, Louisiana State University, West Virginia University, Penn State, and Carnegie-Mellon.

Emerson is proud to have been a founding member of the SMLC. Emerson’s participation began at the initial 2006 workshop that was funded by the National Science Foundation, where industry and academic experts met to brainstorm on the next revolutionary manufacturing technologies that will transform industry.

This output from this workshop eventually led to the formation of SMLC. More recently, Emerson has supported the work of the SMLC with test beds at Praxair and General Dynamics. This effort continues as a member of the CESMII coalition for this Gulf Coast Region.In the blog post referenced above, we highlighted the Praxair work:

…the Praxair test bed, the team was planning to apply novel Emerson temperature and gas analytical techniques on a steam methane reformer. These units are very large furnaces, the size of a small, 3-story house with temperatures that are extremely harsh (~2000 Deg F) on the inside of the furnace.

The team will be researching various temperature technologies including Rosemount high-temperature sapphire sensors, Infrared (IR), and others. Emerson will supply additional O2 and combustible sensors in various locations around the furnace to provide sufficient measurements to solve a high-fidelity model on the Smart Manufacturing (SM) platform.

The objective of this research was to look at best ways to adjust fuel valves to push 96 burners with around 400 tubes in the steam-methane reformer to their metallurgical limits in order to improve hydrogen yield.

Research work between Emerson and the University of Texas Separations Research Program was presented at the CESMII meeting as one of the proposed test beds.

Research work between Emerson and the University of Texas Separations Research Program was presented at the CESMII meeting as one of the proposed test beds.

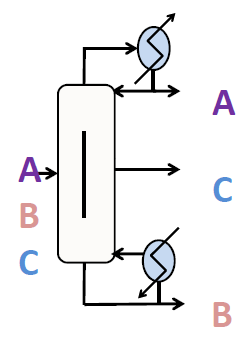

In a post, Divided Wall Column MPC Control with Wireless Instrumentation, we highlighted this research and the potential of divided wall column (DWC) technology. A DWC is:

…a distillation column with a vertical partition that divides the column into two parts—pre-fractionate and mainfractionate. This configuration reduces capital costs by utilizing only one column, and it reduces thermodynamic losses by portioning between the feed and side product.

I’ll check back with Mike and provide updates as the work of the CESMII unfolds in order to advance the state of technology and work practices in improving chemical manufacturing performance.