The exchange of crude oil between seller and buyer is known as custody transfer. A simple example of this is the gas pump where you fill up your car. The pump must accurately measure the fuel and determine/collect payment for the amount transferred into your gas tank.

Lease Automatic Custody Transfer (LACT) units facilitate this transfer in an automatic way, both in onshore and offshore oil & gas production operations.

I found that these LACT units go back in history to 1948, where:

The first experimental field installation of a LACT unit was made by Shell Oil in February 1948 in Antelope Field Texas. It was not until December 22, 1955 that the first routine transfer of custody of crude oil through a LACT unit took place. The transfer was made from the lease of the Gulf Oil Corp. to the Kaw Pipe Line Company in Bloomer Field in Kansas.

I share this because I discovered a great whitepaper, Lease Automation Custody Transfer (LACT), by Emerson’s Dean Minehart.

I share this because I discovered a great whitepaper, Lease Automation Custody Transfer (LACT), by Emerson’s Dean Minehart.

He opens describing the critical importance of LACT units:

LACT units are a necessary means to generate revenue from a production facility.

Guidance for the components of a LACT unit is described in API Manual of Petroleum Measurement Standards (MPMS) Chapter 6.1 and units with Coriolis flow meters are described in API MPMS Chapter 5.6.

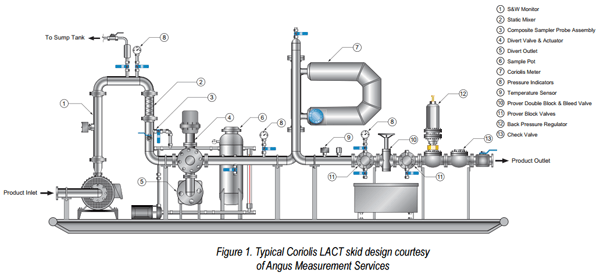

Dean highlights and describes the components typically found in the design of a LACT skid:

A centrifugal charge pump moves the fluid from the inlet through the skid. A sediment and water (S&W) monitor:

…measures the dielectric constant of the flowing fluid. These devices monitor the flowing fluid and determine whether the flowing crude oil is merchantable. Merchantable crude oil must have an S&W content below a certain percentage by volume (often less than 0.5%).

Downstream is a static mixer, sample probe and solenoid valve in order to flow the fluid into a composite sampler:

…to determine a batch average API Gravity (ρb ) and S&W which is used to calculate Net Standard Volume. It is important to close the sample inlet when non-merchantable oil is being diverted and proportionally sample merchantable oil through the sales flowmeter.

Downstream a divert valve routs:

…flow from the LACT inlet to the divert outlet. Divert outlet flow may be routed to a slop tank or a low pressure separator/heater treater on the lease for reprocessing.

When the S&W monitor determines the flowing crude meets the contract specification for sale:

…the divert valve switches to route flow through a downstream sales flow meter.

A Micro Motion ELITE Series Coriolis flowmeter is used for the sales flowmeter mounted in a flag (vertical) position with the fluid flow up through the meter. The transmitter off this flowmeter:

…produces gross volume pulses required for meter proving and provides a user interface to the meter. Fluid temperature and pressure measurements (Items 8 and 9) are directly downstream of the sales flowmeter.

Downstream of these measurements, valves:

…facilitate a portable meter prover. The in-line prover block valve is a double block and bleed valve which ensures that no valve leakage bypasses a prover. LACT sales flowmeters are typically proven on a monthly basis.

In an earlier post, Proving Flow Measurement Accuracy for Hydrocarbon Applications, we described the operation of these portable provers.

With that basic description of the components and their role in this automated custody transfer process, you’ll want to read the whitepaper for more on the operation of the LACT unit in concert with stock tank levels and various means of distribution from pipelines to truck trailers and railcars. Dean shows the calculations involved in determining Net Standard Volume (NSV) including correction factors, temperatures, pressures and sediment & water levels.

Here is where you can find out more on other flow and density metering for oil & gas production management, enhanced oil recovery, chemical injection, oil treatment and storage and natural gas treatment & compression.

You can also connect and interact with other oil & gas and flow measurement experts in the Oil & Gas and Flow groups in the Emerson Exchange 365 community.