Emerson’s Lydia Miller let me know about a new whitepaper, Using Automation to Improve Plant Heat Rate that highlights ways to improve the efficiency of this conversion from thermal to electrical energy.

The whitepaper opens by describing what goes into the heat rate calculation:

The whitepaper opens by describing what goes into the heat rate calculation:

The plant’s heat rate is calculated from the combined performance of all auxiliaries in the plant. The input energy is the chemical energy in the fuel and the power generated is the gross or net generation in kW. Heating value is the amount of heat that is released during the combustion of a specified amount of fuel. The higher heating value, or higher calorific value, is determined by the fuel’s original pre-combustion temperature when the water is in a liquid state, and is a quantity that is used when latent heat or vaporization of water is present.

It notes:

Improving fuel usage and optimizing the system will reduce heat rate and eventually lead to a more profitable operation.

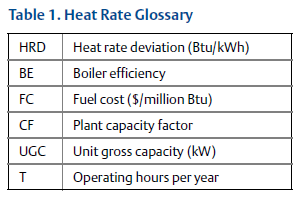

Fuel usage constitutes a large portion of the operating budget. Here is a formula to determine how changes in the heat rate affect annual fuel costs:

HRD/BE x FC x CF x UGC x T=change in annual fuel cost ($/year)

For example, for 500MW coal-fired plant with a boiler efficiency of 85%, fuel costs of $2/MMBTU and an 80% plant capacity factor, fuel cost could be reduced by more than $8,000 per year for each unit (BTU/kWh) of heat rate reduction.

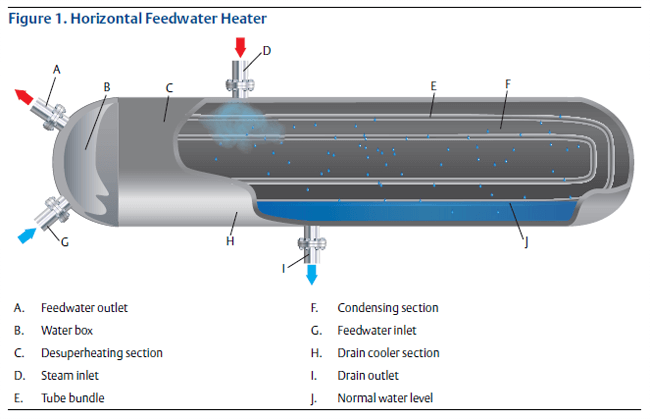

The whitepaper highlights the feedwater heater and ways to improve the heat rate to yield these economic improvements. I’ll highlight a portion from the whitepaper and invite you to read the rest.

Three process variables are key to monitor—Terminal Temperature Difference (TTD), Drain Cooler Approach (DCA) temperature and feedwater Temperature Rise (TR). TTD:

…assesses how close the outlet feedwater temperature is to the feedwater saturation temperature, or in other words, the capability of heat transfer in the feedwater heater. The objective is to achieve a feedwater temperature as close to the steam inlet temperature as possible because the higher the TTD the poorer the performance of the feedwater heater. A feedwater heater is designed with a target TTD that often is around 5 °F (3 °C).

DCA:

…is a measure of how close the heater drain outlet temperature is to the feedwater inlet temperature. A lower DCA temperature is better than higher, but the feedwater heater is designed with a target DCA temperature for optimal performance. If the DCA temperature is too high, it can lead to damaged tubes, as well as drain cooling zone end plates and baffles.

TR, the:

…difference between the feedwater outlet and the feedwater inlet is measured and the goal is to hit the specified target.

Suboptimal readings of these variables indicate wasted energy, which can be caused by tube fouling, plugged tubes, inadequate venting and tube leakage. The liquid level in the feedwater heater must be controlled closely to avoid having the boilers operate with reduced efficiency and increased net unit heat rate. Too much water can also lead to safety issues caused by turbine water induction.

Download the whitepaper to see how guided wave radar level measurement technology can successfully handle these difficult temperatures, pressures and changing density and dielectric properties that negatively affect other level measurement technologies.

You can also connect and interact with other level measurement experts in the Level group of the Emerson Exchange 365 community.