I managed to get my hands on a great paper, Olefin Plant Energy Savings through Enhanced Automation, written by Emerson’s Dr. Douglas C. White, whom you may recall from earlier posts. Doug is a principal consultant who leads the Process Improvement and Optimization Consulting team.

He presented this paper at the AIChE Spring National Meeting as part of the Ethylene Plant Technology – Energy Consumption and Optimization track. The abstract:

Energy is the single largest controllable cost for olefin plants and the recent rise in prices has caused most plants to look even more closely at their usage. Automation and advanced automation can significantly reduce usage across all areas of the plant. Some of these savings can be achieved with no investment, only changes in normal operating procedures. In other cases improvements to on-line analyses, measurements and control action are justified but generally require relatively modest investments. The management of the utilities at a major olefin site can be difficult with many daily operating decisions that must balance competing economic and production issues. Real time modeling of process and utility equipment and monitoring of the energy usage in plants permits allocation decisions to be made much more frequently and accurately, often resulting in substantial savings.

Doug describes the economics that Olefin producers face:

Olefin plants are large energy consumers with energy the largest variable operating cost after feedstocks. Using energy efficiently has been and remains a primary goal for olefin producers.

Natural gas is the marginal fuel consumed and its price has been a source of volatility over the past several years. Doug describes surveys where there is at least a 40% spread in energy usage between the most and least efficient plants. The source of this variation is due to the age and efficiency of the equipment and the heat integration.

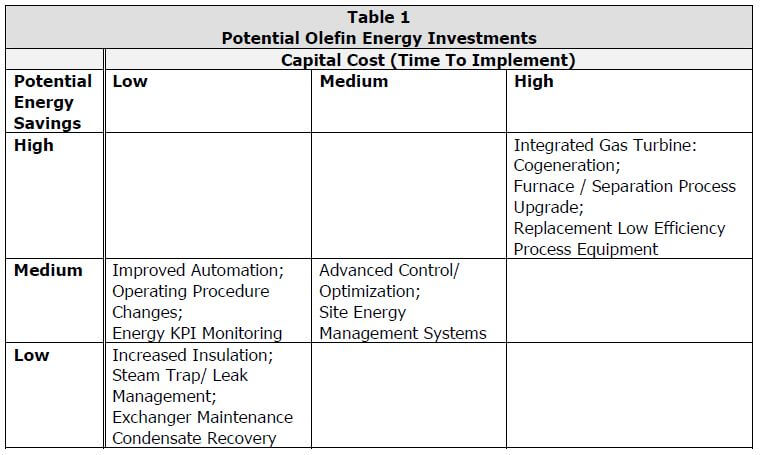

Doug provides an energy investment opportunity matrix of high, medium, and low potential energy savings versus capital cost/time to implement. An example of a potentially high energy saving opportunity, but coming at a high capital cost is and integrated turbine. At the other end (low savings / low investment) are things like increased insulation and heat exchanger maintenance.

He describes two ways to reduce energy costs–either by reducing supply costs or reducing process energy demand. On the supply-cost side, the focus is to increase internal utility production efficiency and reduce external purchase costs. Advanced control and optimization on the furnaces, quench/fractionators, compressors, and distillation columns are a few examples cited on the process energy demand reduction side.

The paper describes areas to find energy savings. These include: control loop performance improvements, more accurate measurement of process variables, measurement additions via WirelessHART technology, valve performance improvements to handle the various olefin plant load conditions, loop dynamic analysis and tuning, and steam system management and control. The paper provides further thoughts in each of these areas.

Doug recommends developing an automation energy savings program and beginning with a full assessment of current operating conditions. This not only helps with the justification, but also provides the benchmark to compare improvements against to provide return on investment. He counsels that a part of this assessment is to identify the control and advanced control loops that have a major impact on energy usage. He has another matrix of energy loss consequences versus historical frequency for monitoring and maintenance. This analysis helps prioritize financial impact and focus the justification efforts.

Whether or not you’re an Olefins producer, you’ll gain some insight in how to find and plan a path to energy savings.