Plants need a strong pipeline of data to help them ensure optimal performance. We spend a lot of time talking about how to collate, transmit, and store that data so it is easily accessible whenever and wherever people need it. However, all that strategizing is of...

PeakVue

Navigate Data Difficulties with Enterprise Asset Management

Few process manufacturing teams today are struggling with having too little data. On the contrary, many organizations are overwhelmed by the massive amounts of data streaming in every day from their field devices and collected during scheduled rounds. Much of that...

Wireless Data on Demand Helps Make the Most of Reliability Personnel

Today’s shortage of experienced plant personnel comes as no surprise to anyone. But the optimal solution to that problem might be a bit less obvious than the problem itself. Those retiring workers aren’t coming back any time soon, but plants still need to find ways to...

Expert Advice for Alarm Management

Effective alarms are one of the most important elements of a safe plant. However, setting up an effective process alarm solution is a stumbling point for many teams. There are ways to create better alarm management, but they aren’t always intuitive. Fortunately,...

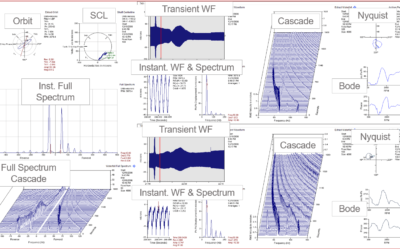

Joseph Fourier is Way More Cool than Louis Vuitton or Christian Dior

Much of our vibration analytics today are still based on Fourier Transform which analyzes complex vibration by superpositioning a variety of sines and cosines waves of different but related frequencies.

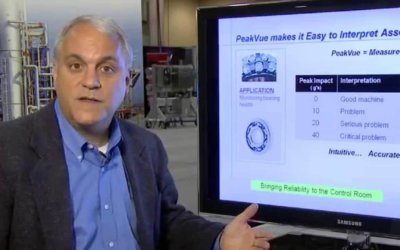

Advanced Analytics for Detecting Anti-Friction Bearing Faults

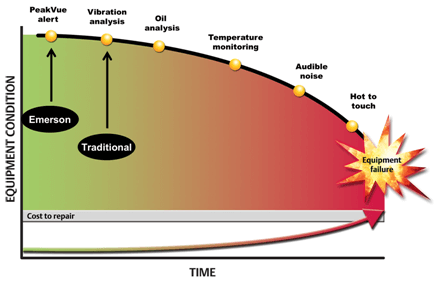

In a new paper, Using PeakVue Plus Technology for Detecting Anti-Friction Bearing Faults, Emerson’s Stewart Bowers describes how PeakVue Plus analytics innovation to PeakVue automates the analysis of PeakVue analytics and presents the results in a user-friendly format.

Improving Reliability with Impact Detection Analytics

Operational analytics are used to help improve safety, reliability, energy & emissions, and production. From a reliability perspective, one example is PeakVue impact detection analytics which provides early warning for problems such as rotating equipment bearing...

Ovation Advanced Condition Monitoring

Emerson's Jason King shares an update on advanced condition monitoring in the Ovation distributed control system at last week's 2019 Ovation Users' Group conference. This integrated machinery protection and condition monitoring module built directly into the Ovation...

Diagnosing Gearbox Defects

In earlier posts, Emerson's Robert Skeirik highlighted how PeakVue impact detection analytics technology can provide early warning of bearing failure in time to plan and schedule maintenance before unplanned downtime occurs. These analytics help drive overall...

PeakVue Analytics for More Reliable Machinery Performance

Yesterday, in a post, How to Prevent Bearing Failures, we described how PeakVue analytics technology can provide early warning for bearing problems. In this 6-minute YouTube video, PeakVue Signal Processing Demo, Emerson's Robert Skeirik describes how these advanced...

How to Prevent Bearing Failures

Rotary bearings for industrial machinery reduce to friction between the moving parts. As with other mechanical parts, they wear over time. In a Plant Services article, 6 steps to preventing bearing failure, Emerson's Brian Overton shares ways to extend bearing life...

Avoiding Forced Outages from Rotating Equipment Issues

The reality for manufacturers and producers is that their plant assets continually degrade over time. Valves wear over time, electrical assets may experience intermittent faults, and rotating equipment imbalances may lead quickly to forced outages. In this 3-minute...

Keep Up to Date With the Latest News and Updates

Follow Us

We invite you to follow us on Facebook, LinkedIn, Twitter and YouTube to stay up to date on the latest news, events and innovations that will help you face and solve your toughest challenges.

Do you want to reuse or translate content?

Just post a link to the entry and send us a quick note so we can share your work. Thank you very much.

Our Global Community

Emerson Exchange 365

The opinions expressed here are the personal opinions of the authors. Content published here is not read or approved by Emerson before it is posted and does not necessarily represent the views and opinions of Emerson.